The shot blasting machines is designed for cleaning of pipes up to the 2nd treatment degree according to PSA 2 1/2 ISO 8501-2 in stationary conditions.

Shot blasting machines are designed for cleaning the outer surface of pipes from rust, scale, and technological contaminants, as well as for surface preparation prior to applying protective coatings.

Areas of Application

- Steel pipe production for various purposes.

- Oil & gas, chemical, and energy industries.

- Metallurgical and mechanical engineering plants.

- Pipeline anticorrosion protection and painting lines.

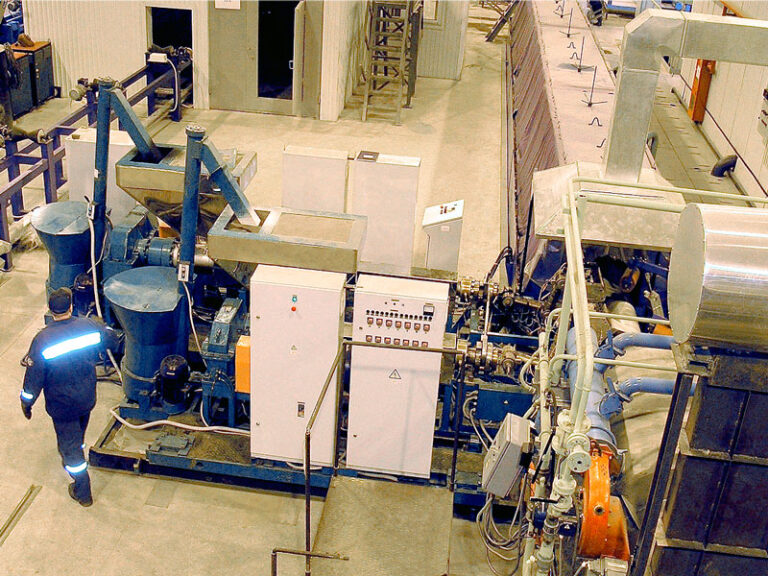

Design Features

- Transport system: roller or conveyor type.

- Working units: turbine shot blasting wheels positioned at optimal angles.

- Lining: wear-resistant materials for chamber protection.

- Shot recycling system: separation and reuse of abrasive.

- Dust extraction: air cleaning and filtration system.

- Control: panel with adjustable operating modes.

Specifications

| Index | Types | ||

| NTP-1 | NTP-2 | NTP-3 | |

| Ø of pipes to be cleaned, mm | 57-325 | 57-630 | 630-1420 |

| Min length of pipes, mm | 7000 | ||

| Linear velocity of pipe treatment, m/min | 0-8 | 0-4 | 0-4 |

| Microasperity height of treated surfaceсу, µm | 40-80 | ||

| Adjusted power, kW | 22 | 50 | 57 |

| Weight of equipment, t | 5.4 | 14 | 18 |

| Overall dimensions, mm | 3400x3700x4500 | 5400x5100x5850 | 6200x5400x6500 |

Articles

- Shot blasting equipment: purpose, types, characteristics

- Overview of popular shot blasting equipment models

- Removal of abrasive residue and dust after shot blasting | Surface preparation for painting

- Evaluation of dust content of steel surfaces before painting – ISO 8502-3

- Preservation lines: shot blasting and painting in one solution