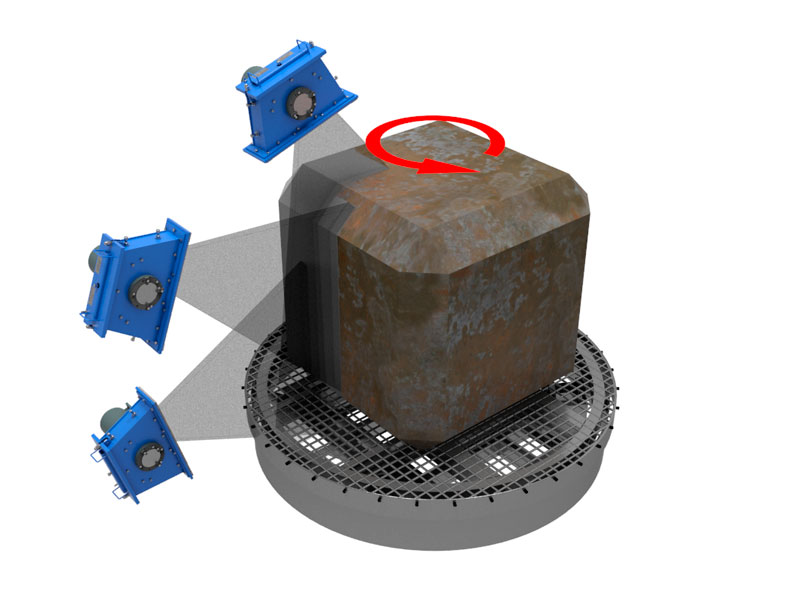

Shot blasting chambers with a turntable have various dimensions and are made with a table size from 1000 mm to 3500 mm. A required configuration of the shot-blasting plant is determined depending on the specifications of the processed items, required performance, and the production conditions of the customer.

| 1.Working chamber | 6. Metal structure |

| 2. Elevator | 7. Carriage with a turntable |

| 3. Separator | 8. Cyclones |

| 4. Shot separator | 9. Filtering plant |

| 5. Shotblasters (3 pcs.) |

Application of shot blasting chambers with a turntable

Shotblasting chamber with a turntable is a multipurpose solution for productions where high efficiency is not needed. Blasting on the turntable allows cleaning odd-shape large and small items. If post-treatment of hard-access sectors is necessary, then a manual shot blasting by an operator (inside the chamber) is possible.

Operation principle

Processed items are loaded onto a carriage turntable manually or with a shop crane The cart with items is rolled into the chamber, the gate is closed, exhaust ventilation and separation device mechanisms are switched on. The turntable starts rotating. Shot blasting devices drives are switched on and the parts are cleaned with a shot.

Specifications

| Type | DPS-1500 | DPS -2500 | DPS -3500 |

| Maximum diameter of table (mm) | 1500 | 2500 | 3500 |

| Operating height of table (mm) | 750 | 760 | 780 |

| Max. workpiece weight (kg) | 2500 | 5000 | 8000 |

| Max. workpiece height (mm) | 1000 | 1400 | 2000 |

| Number of blast wheels | 2 | 2 | 3 |

| Power per blast wheel (kW) | 2х7,5 | 2х11 | 3х18 |