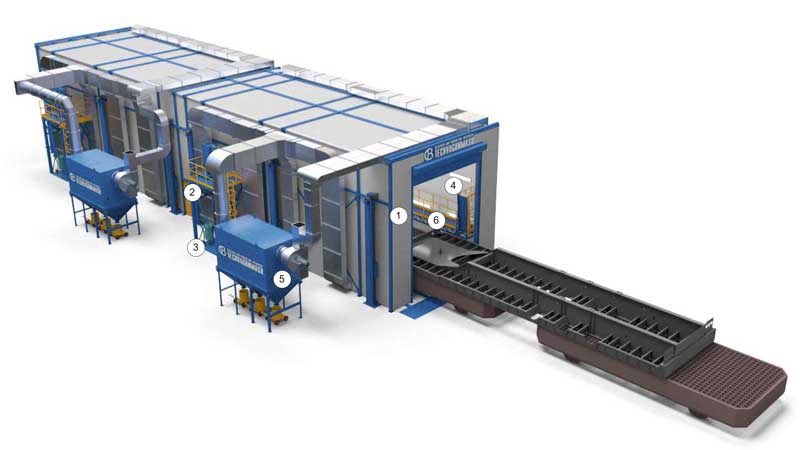

The blast rooms is designed for cleaning of welded metalware with shot. The supply of metalware to the chamber is performed by the carriage.

| 1. Chamber frame | 4. Lighting system |

| 2. Shot circulation system | 5. Air cleaning system |

| 3. Shot blasting machine | 6. Lifting platforms |

Additional equipment:

Components description

Chamber frame

The frame of the chamber consists of sandwich panels mounted on load-bearing metalware. Inner walls and a ceiling are lined with a rubber blanket 1.0×3.0 and 1.0×2.0 preventing walls and abrasive material wear. The chamber is equipped with one swing entrance gate. The drive of the gate opening is pneumatic type. Control over the gate closing is performed by means of limit switches mounted on pneumatic actuators. The operators can enter the chamber through the door in the lateral side. Closing of the door is performed by means of a limit switch.

Shot circulation system

Shot circulation system is designed for collection of shot thrown out by the shot blasting unit, its separation and feed to the shotblasting unit.

The shot circulation system consists of:

- scraper conveyors;

- elevator;

- separator.

Overalls for the operator

Operators are equipped with a full set of individual protective overalls and a system of preparation and supply of the air for breathing. Depending on the season the climatic system has two modes of air preparation for operator’s breathing – heating and cooling.

One set includes:

- air cleaning filter for breathing;

- protective overalls;

- safety helmet;

- cuffed gloves.

Air cleaning system

Ventilation system consists of filter plant, radial fan, air ducts, service platform and provides removal of dusty air out of the work chamber, its cleaning and emission to the atmosphere. Shaking of the cartridges from the dust is performed through the feed of a short pulse of compressed air to the cartridge. In addition to this the dust accumulated on the cartridge falls to the dust collection hopper, and the process of air filtration does not stop.

Equipment Orders

To place an order for a blast room, please download and complete the questionnaire, and forward it to the following email address: market@tvagonm.com.ua.

For further consultation regarding the manufacturing of blast rooms, you may contact us by phone at:

+38 (067) 818-18-20 (WhatsApp)

Photo

Articles

- Shot blasting equipment: purpose, types, characteristics

- Overview of popular shot blasting equipment models

- Removal of abrasive residue and dust after shot blasting | Surface preparation for painting

- Evaluation of dust content of steel surfaces before painting – ISO 8502-3

- Preservation lines: shot blasting and painting in one solution