The shot blasting machine cleans sheet and rolled profile metal removing scale, dirt and rust. The chamber with protection has a closed metal construction covered inside with rubber sheets to absorb cinematic shot energy. The sheet and rolled profile metal is directed by a transport device into the shot blasting chamber where it is treated automatically. Then, the metal comes into the final purification chamber where dust and shots are removed. The regeneration of used shots takes place continuously in closed cycles charging shots by a screw conveyor an elevator into the separator, shot eliminator and then into the hopper.

By request of the Customer we can deliver roller conveyors, racks for loading and receiving as well the air cleansing system

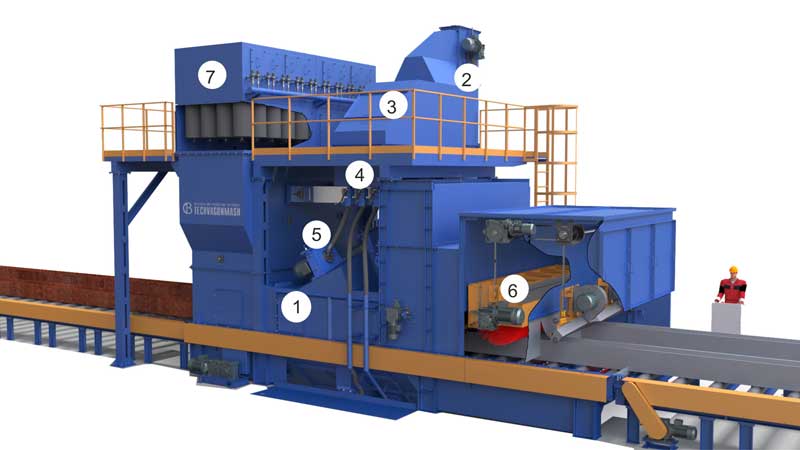

| 1. Сhamber | 5. Shot blasters |

| 2. Elevator | 6. Shot remover brush |

| 3. Separator | 7. Ventilation and filtering system |

| 4. Shot bunker | |

Roller conveyor shot blast machines applications

- Cleaning metal plates and profiles

- Corrosion removal

- Paint Stripping

- Rust and Heat Scale Removal

Specifications

| # | Index | Model |

|---|

| | KD-800 | KD-1600 | KD-2600 | KD-3200 |

| 1. | Max. Passage width | 800 | 1600 | 2600 | 3200 |

| 2. | Max. Passage height, mm | 350 | 500 | 500 | 500 |

| 2. | Possible working speed, m/min | 0.5-2.5 | 0.5-2.5 | 0.5-2.5 | 0.5-2.5 |

| 3. | Microasperity height of treated surfaceсу, µm | 40-80 |

| 4. | Quantity of turbines | 4 | 4 | 6 | 6 |

| 5. | Adjusted power, kW | 92 | 116 | 120 | 210 |

| 6. | Weight of equipment, t | 9.5 | 27 | 30 | 42 |