In modern steelmaking, shipbuilding, and mechanical engineering, high-quality shot blasting plays a crucial role. Specialized shot blasting machines are used to remove scale, rust, and contaminants, as well as to prepare metal surfaces for subsequent coating and painting.

The Techvagonmash designs high-performance shot blasting machines for various industrial sectors — from shipbuilding to heavy machinery manufacturing. The design and type of equipment depend on the shape, size, and specific features of the processed components. In this article, we’ll review the most popular shot blasting systems and their key characteristics.

Shot blasting requires an individual approach depending on the type of product: sheet and profile rolled steel, round bars and pipes, welded structures, heavy machinery components, and shipbuilding parts. For each type of item, there are specialized machines that ensure high-quality and stable processing.

Most Popular Shot Blasting Machines

Roller Conveyor Shot Blasting Machines for Sheet and Profile Rolled Steel

A classic roller conveyor shot blasting machine is suitable for processing components with simple geometries: sheet metal, profiles, beams, and pipes.

- Processing width: up to 3.2 meters

- Processing height: up to 500 mm

The workpieces move smoothly and continuously along the conveyor, ensuring consistent cleaning quality. These machines are known for their low maintenance requirements and high reliability.

Optional features include:

- Air-blow units for removing moisture and contaminants

- Pre-drying chambers for eliminating ice and snow — particularly useful when preparing components for protective coatings.

Shot Blasting Machines for Welded Metal Structures

Designed for large and heavy welded structures, pipes, profiles, and long flat parts, these machines feature:

- Increased pass-through dimensions

- Reinforced construction for heavy loads

They can handle components up to several meters long, up to 4 meters wide, 1.6 meters high, and weighing several tons.

Thanks to powerful blasting systems and flexible design, they deliver high-quality cleaning even on complex welded assemblies with hard-to-reach areas. Additionally, the system can be optimized for specific production conditions, reducing costs and improving efficiency.

Shot Blasting Mashines with Overhead Conveyor Systems

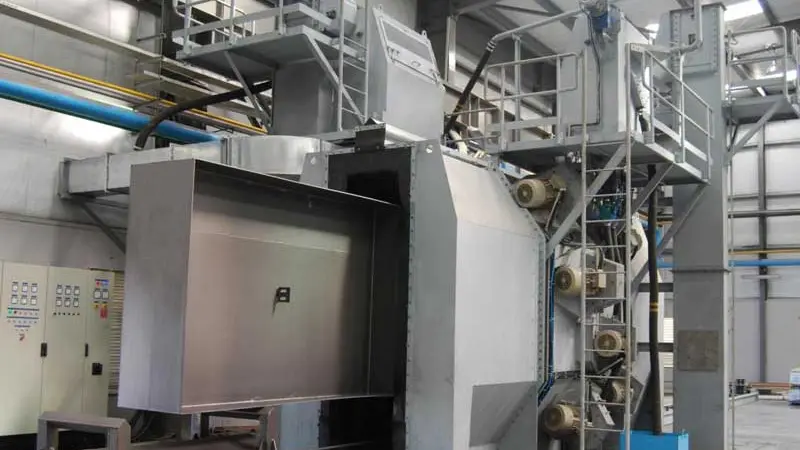

For mass processing of large and heavy parts, such as components for railway equipment, construction machinery, and agricultural machinery, an overhead conveyor shot blasting machine is the optimal choice.

- Max processing height & width: up to 3.5 meters

This setup allows simultaneous processing of multiple large components, significantly improving throughput.

Shot Blasting Machines with Turntable Systems

A turntable shot blasting machines is a versatile solution for facilities where high productivity is not required.

- Suitable for both large and small items

- Handles complex geometries effectively

For shadowed areas that are difficult to reach automatically, manual shot blasting inside the chamber can be performed by an operator.

Shot Blasting Machines for Pipe Cleaning

Designed specifically for steel pipes with diameters up to 1,420 mm and lengths of several meters, these systems feature:

- Rotating rollers that move the pipes along a conveyor

- Simultaneous rotation of the pipes for uniform cleaning

The machine ensures consistent and high-quality treatment of the pipe’s outer surface in a continuous production mode. Moreover, it can be easily integrated into existing production lines, improving both efficiency and product quality.