Industrial paint booth has been deisgined for painting and drying of welded metal structures. Painting and drying of small size products is possible in suspended position (with installation to industrial trucks of special tools of “pyramid” type).

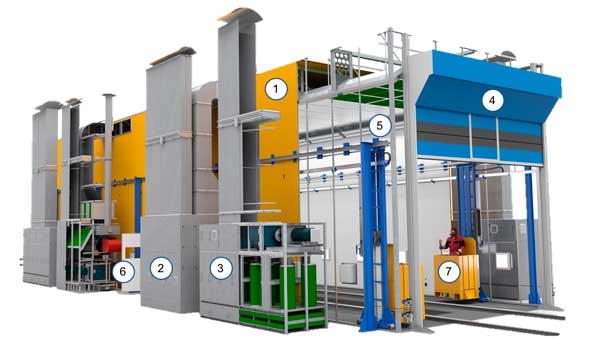

| 1. Booth body | 5. Lighting of the booth |

| 2. Heat generator | 6. Emergency exit |

| 3. Air cleaning system | 7. Pneumatic access platforms |

| 4. Gates |

Options

Description of component parts

Body of industrial paint booth

The body of industrial paint booth is a bearing structure made of aluminun pipes and galvanized steel double panesl with foamed polyurethane inslation. The panels are mortised which guarantees minimal assembly time.

Roll-down door

The roll-down door of the paint booth are equipped with flameproof electrical drive and complete with two remote position controls. All mechanisms are protected from the paint mist. It assures long perfomance life and prevents the sandwith film buildup on swing joints and sliding surfaces.

Opposite to traditionally used sectional gates with manual opening, this door does not warp in operation process, their opening / closing stays easy.

Heat generator

The heat generator is a special set of equipment, designed for air cleaning, heating and supply to the booth with its further extraction. At different process cycles or heating modes the exhaust air can be partially or completely supplied back to the working areas through regulated recirculation system.

The heat generator is a module structure consisting of several wire-framed blocks. The blocks panels are made of galvanized steel with mineral cotton thermal insulator.

Air cleaning system

Air cleaning system has been designed to clean the vented air from painting mist and solvent vapor.

The air, coming out of the booth in the process of painting or drying is cleaned by activated carbon filters.

The cleaning process is as follows:

1. The air, contaminated with painting mist and solvents vapor is sucked from below of the booth passing through two rows of rectangular filters in the booth floor.

2. After than the precleared air goes to the hose fine filter filled with activated carbon. Than the air cleaned from the solvent vapor goes throught the activated carbon to the atmosphere.

Lighting of the booth.

The painting and drying booth is equipped with lamps of explosion-proof design ip65. The lamps provide the 1000 lx shadowless lighting. The lamps structure is easy to maintain which maximally facilitates the work of service personnel.

Control panel

The control panel allows programming and bringing the booth into different operation modes (painting, grounding, drying) with different temperature and period. The devices on the control cabinet sustain the voltage peaks ±20%, electrical motors – ±10%. The booth is equipped with pressure and temperature control detectors inside and outside the booth.