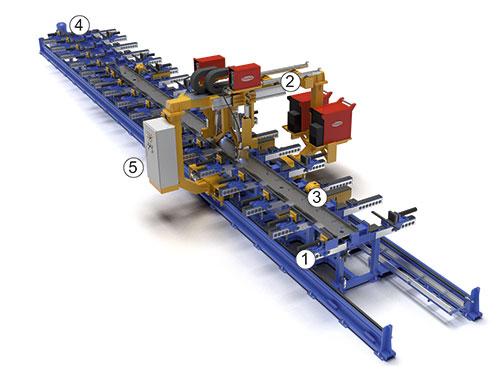

The line is designed for assembly and automatic welding of semitrailer girders.

| 1. Stand for girder assembly | 4. Hydraulic unit |

| 2. Welding gantry | 5. Control cabinet |

| 3. Rotator |

Specifications:

| 1. | Overall dimensions and weight of the assembled item: | |

| length max, mm | 14200 | |

| width max, mm | 220 | |

| height max, mm | 700 | |

| weight max, kg | 1000 | |

| 2. | Parts fixation principle | Hydraulic |

| 3. | Realignment principle | Mechanical, manual |

| 4. | Control principle | By means of buttons |

| 5. | Gantry for automatic welding of girders | |

| Welding speed, m/h | 0,5…0,6 | |

| Inoperative speed, m/h | 15 | |

| Speed regulation principle | frequency | |

| Seam tracking principle | mechanical | |

| Seam type | t-weld | |

| Number of simultaneously welded seams, pcs | 2 | |

| Gantry travel drive | electromechanical | |

| Drives number, pcs | 2 | |

| Torque on the drive shaft, N.m | 110 | |

| 6. | Parts clamping principle | pneumatic |

| 7. | Air pressure in the air main, MPa | 0,5 … 0,6 |

| 8. | Installed capacity, kW | 40 |

| 9. | Number of welding semiautomatic machines, pcs | 2 |

| 10. | Welding semiautomatic machine power source | Fronius |

| 11. | Overall dimensions of the line, mm | 18300х4156х2988 |

| 12. | Weight, kg | 12000 |