Automated drilling center is designed for performing of manufacturing operations connected with drilling of hoes drilling in freight cars center sills. Machining is carried out automatically in two mutually perpendicular planes per one operation.

The holes for rivets are made on the stand for stops mounting ( the stops with top center plate ), wear-resistant plates, manufacturing holes, holes for mounting of support plate and brake equipment brackets.

Advantages:

- complete machining per one operation;

- machining is performed automatically without preliminary marking;

- availability of chip removing conveyors provide high production standard, reduces time for stand cleaning.

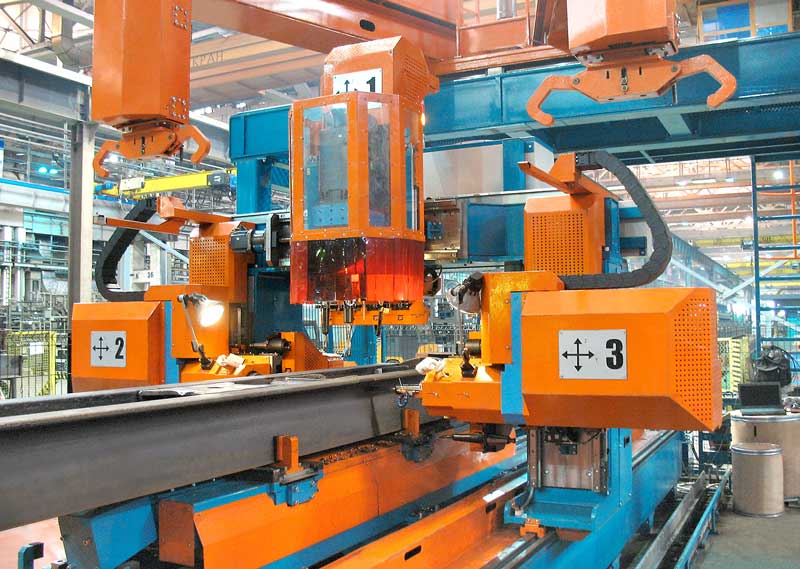

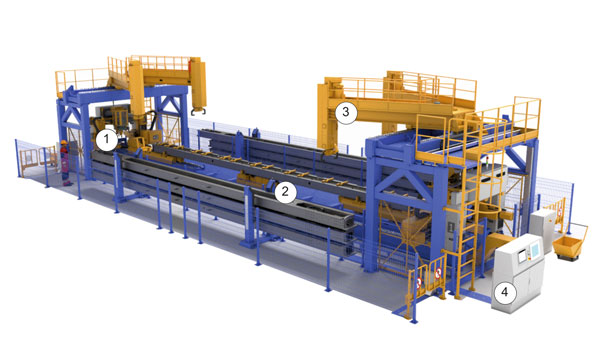

| 1. Drilling gantry (2 pcs.); | 3. Loading/unloading device; |

| 2. Clamping table; | 4. Remote control. |

Specifications:

| 1. | Machine item | Center sills of all gondola and hopper cars models |

| 2. | Drilling gantry: | 2 pcs |

| Number of drilling heads on the gantry horizontal/vertical | 2/1 | |

| Type of drilling heads applied | (Somex) Suhner | |

| Tool system type | ISO 40 | |

| Number of replaceable tools storage units on each gantry | 3 | |

| Number of places in each storage unit | 4 | |

| 3. | Clamping table : | |

| Item fixation principle | Hydraulic | |

| Number of clamps and rammers | 2+4 | |

| Integrated hydraulic unit | yes | |

| 4. | Machined item measuring system | Contact probe |

| 5. | Air consumption, m3/h | 5 |

| 6. | Pressure, MPa | 0.6…0.7 |

| 7. | Installed capacity, kW | 95 |

| 8. | Overall dimensions with standard features, mm | 21410 х4300×3020 |