The line is designed for shot blast cleaning (up to 2nd degree according to GOST 9.402-80 (PSA2½ ISO 8501-2)), priming and drying of the surface of sheet and profile rolled products.

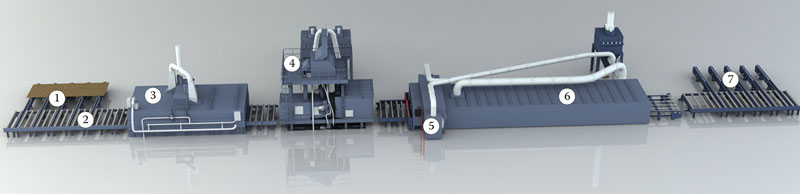

| 1. Loading rack | 5. Prime coating chamber |

| 2. Conveyor system | 6. Drying chamber |

| 3. Drying chamber | 7. Receiving rack |

| 4. Shot blasting chamber | |

Drying and heating chamber

Drying and heating chamber dries rolled metal and heats it till 35-45ºC shortening the heating time after scale removal and preservation. By request of the Customer we can produce this chambers with diesel and gas heating.

Shot blasting chamber

The shot blasting chamber is designed for shot blasting (till the 2nd purification efficiency acc. to GOST 9.402-80 (PSA2½ ISO 8501-2). The purpose of the chamber is to clean sheet rolled metal surfaces. The shot is thrown to the surface by blaster blades. The shot blasting velocity runs up to 80-90 m/c. when the shot comes into the contact with the surface the removal of rust, scale, dirt reaches the 2nd purification efficiency acc. to GOST 9.402-80 (PSA2½ ISO 8501-2). Depending on the capacity or rolled metal sizes there are 4 to 8 blasters in the chamber. The chamber have an air cleansing system with air suction.

Prime coating chamber

The prime coating chamber is intended for colouring of quick-drying primers in an automatic mode. The chamber is equipped nozzles which paint the rolled metal surfaces and can use almost all the primer types. It has a regulating system which allows to paint with thickness 15 to 70 µm.

Drying chamber

The drying chamber dries the primer on rolled metal surfaces. When drying the chamber works in a recirculation mode sucking in 10 – 15% fresh air from atmosphere to prevent the excess return air from solvents avoiding explosive mixture build-up. As a result of recirculation the drying mode is very efficient (electrical consumption is lower, fuel consumption is only 40% in comparison with painting mode). During recirculation the air passes through primary filters, floor and bottom filters.

Conveyor system

The conveyor system transfer rolled metal to technological steps. The roller conveyors have a smooth speed regulation.