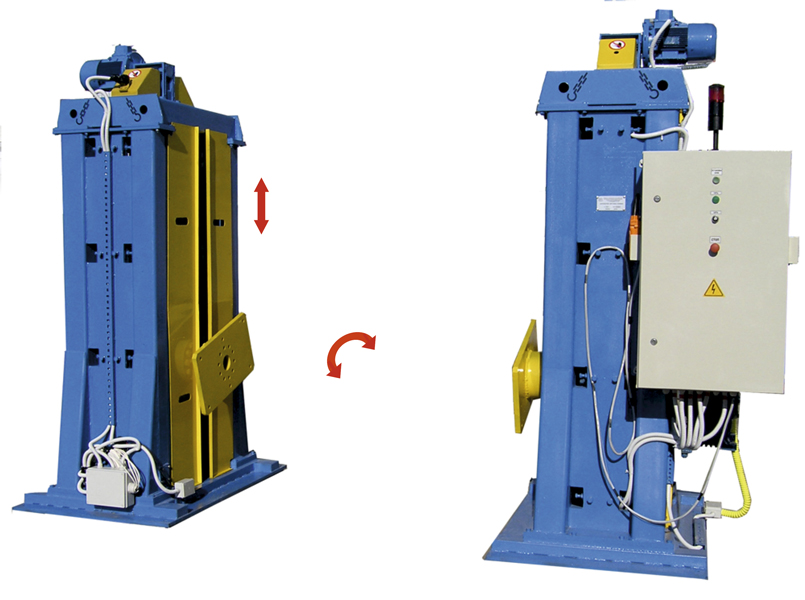

Headstock and tailstock positioners are used in various industries to place, lift and swivel frame steelwork into a suitable welding position. With the weld positioned horizontally, they provide the best conditions for forming a quality weld.

The range of models and capacities of headstock and tailstock positioners is very wide and can vary from a few hundred kilos to tens of tonnes. The positioners are used in the railway, automotive, energy and aviation industries.

The major advantage of using positioners is that they allow you to work faster and more efficiently, as they make it easier to access the weld and allow the welder to work in the most comfortable working position.

Having been designed in accordance with European safety standards and tested for overload in the final stages of production, the positioners are equipped with warning lights and sound alarms.

Available in different version

The positioners are available in 5 different designs:

- One idle column, one driven column;

- Two driven columns (welding of long steel structures);

- Two fixed columns;

- One fixed column, one movable column (welding of different product lengths);

- Design with a support ring.

Also available in versions that feature rotation only or lift only.

Techwagonmash positioners are designed and manufactured according to the specific needs of the customer.

Headstock Tailstock Positioner Features & Benefits:

- possibility of integration into robotic welding centers;

- possibility of different-length products welding;

- when using fixtures, welding of such items as roof, body, etc. is possible;

- designing of positioners taking into account specific characteristics of the welded item (displaced gravity center, structural flexibility, etc.).

Specifications:

| Index | Types | |||||

| HTP-4000 | HTP-6500 | HTP-10000 | HTP-15000 | HTP-20000 | HTP-30000 | |

| Max load capacity, kgs | 4000 | 6500 | 10000 | 15000 | 20000 | 30000 |

| Vertical move, mm | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| Rotation axis height, mm | 750-1750 | 750-1750 | 750-1750 | 750-1750 | 750-1750 | 750-1750 |

| Elevating speed, m/min | 1,6 | 1,5 | 1,5 | 1,3 | 1,12 | 0,7 |

| Rotation speed, rpm | 2 | 1,8 | 1,6 | 1,2 | 0,7 | 0,95 |

| Weight, kg | 3450 | 4500 | 6300 | 8700 | 9700 | 15000 |

Photo