The blast rooms is designed for shot blasting of wagons up to the 2nd degree of cleaning according to Sa 2 ½ ISO 8501-1:2015.

The operator is equipped with a complete protective clothing and a breather. Depending on the year seasons the breather has 2 modes of air supply: with heating and cooling. To do the cleaning of metalworks convenient in the height there are galleries which can be placed to the necessary positions inside the chamber. The chamber is equipped with lighting and venting systems.

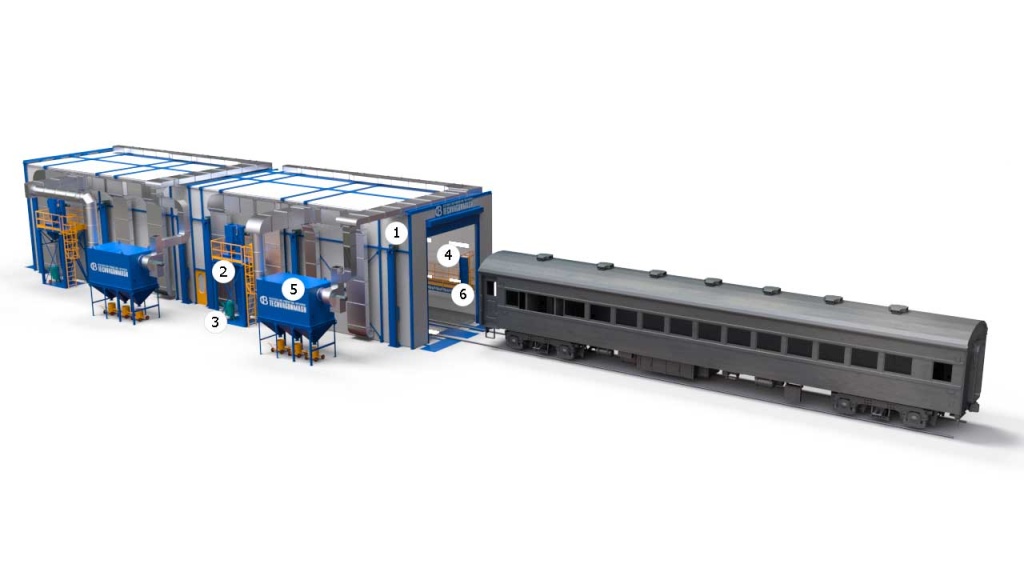

| 1. Working chamber | 4. Lighting |

| 2. Shot circulation system | 5. Air cleaning system |

| 3. Shot blasting machine | 6. Elevating access platforms |

Description of equipment operation

The work is done as follows: the wagon is pulled into the chamber by a winch. The doors are closed, two operators clean the wagon outer surface by shot blasting. Used shots fall through the grid floor in the area with a pusher-bar conveyor which colletct shots in the chamber center in the area of cross conveyors. The shots come into standard cleaning system and into the shot blasters.

| Index | Type | |

| KD-5 | KD-8 | |

| Dimensions of the chamber (inside), mm | 18200x9100x6655 | 29000x9500x7500 |

| Dimensions of the chamber (outside), mm | 18200x9100x6655 | 29000x9500x7500 |

| Pit depth for the elevator, mm | 1500 | 1500 |

| Productivity of two operators (9.5 nozzle), m²/h | 42 | 42 |

| Compressed air consumption with 9.5 mm nozzles and 0.8 MPa pressure, m³/min | 12 | 12 |

| Amount of operators | 2 | 2 |

| Adjusted power, kW | 26 | 30 |

| Air suction volume, m³/h | 14000 | 28000 |

| Weight of the chamber, Tonnes | 42 | 70 |