High-quality surface preparation and interoperation protection of rolled metal products are crucial factors in ensuring maximum service life and the highest quality of protective coatings. This preparation can be achieved through shot blasting, followed by the application of a conductive protective primer on the surface of the rolled metal at the stage of its delivery to production.

Correct surface preparation is one of the key factors affecting the durability of paint and protective coatings. Measuring the level of dust on steel surfaces before painting helps determine whether additional cleaning and preparation are required.

In today’s fast-paced world, logistics and warehousing have become critical success factors for businesses. Companies aim to maximize storage efficiency, speed up order picking, and reduce operating costs.

The research and production firm TECHWAGONMASH has designed and manufactured equipment for a pipe finishing line. The customer for the equipment is the Ukrainian industrial company Interpipe, which has already started the pilot operation of the new line at the Interpipe Niko Tube plant in Nikopol (Dnipropetrovsk region).

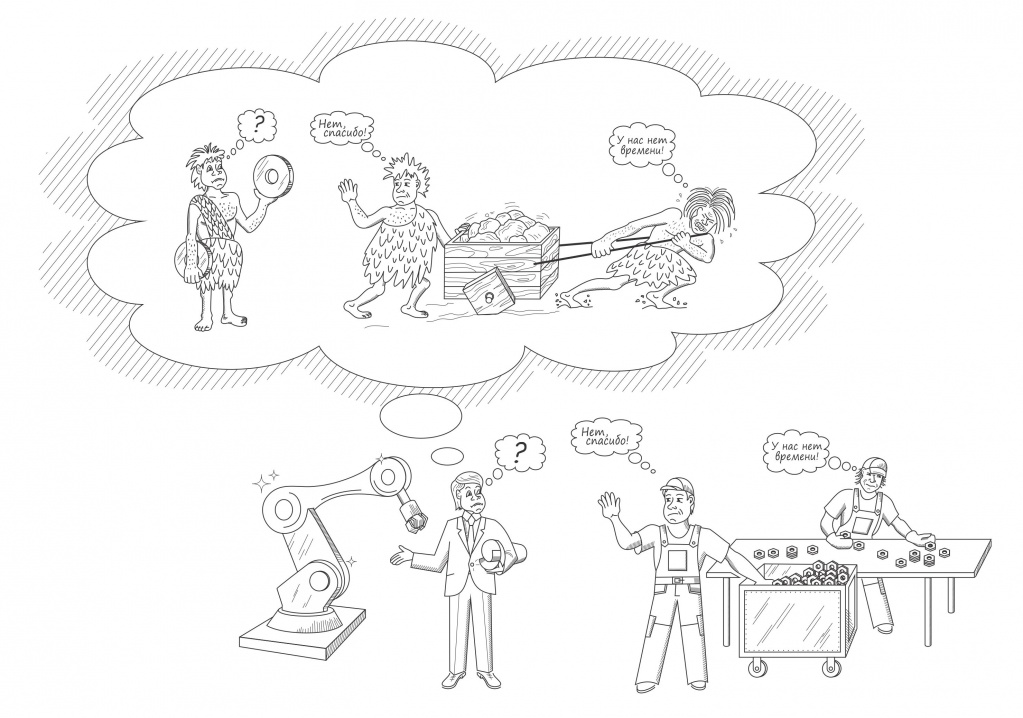

There is a persistent stereotype in the post-Soviet machine-building industry that industrial robots are expensive equipment that requires highly professional personnel and that it is rational to use them in mass or high-volume production. This myth is based on some factors listed below.