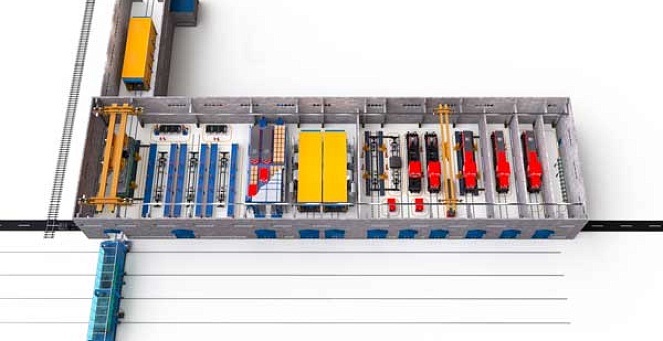

Organization of production for modernization and repair of traction rolling stock

Techvagonmash offers comprehensive projects for the organization of production facilities for the modernization and repair of traction rolling stock (shunting and mainline diesel locomotives, electric locomotives)

Techvagonmash provides a full range of services: from the design stage to the stage of installation supervision and commissioning, including the production of special technological equipment.

Competencies of Techvagonmash

1. Pre-project elaborations;

2. Development of the technological part of the project;

3. Design of special technological equipment;

4. Manufacture of special technological equipment;

5. Installation supervision and commissioning: personnel training;

6. Staff training;

7.Practice technology;

8. Customer service.

Advantages of upgraded locomotives

As a result of modernization, the technical and economic performance of the locomotive is improving.

Its efficiency and traction parameters are significantly increased:

- fuel consumption is reduced by about 20-25% (for example, TEM2 is 450,000 dollars. US$ per life cycle);

- reduction of repair and maintenance costs by 25-30% (for example, for TEM2 it is $ 360,000. US$ per life cycle);

- by increasing the coefficient of technical readiness, it is possible to reduce the number of diesel locomotives at the enterprise.

The updated locomotive is equipped with microprocessor control, monitoring and self-diagnosis systems, such modernization increases the reliability of the locomotive, increases inter-repair runs, reduces the cost of scheduled and emergency repairs