The equipment complex is designed for manufacturing spiral silos. Silos are manufactured directly on the construction site by spiral coiling and double rolling of coiled steel.

The installation is carried out with the help of special equipment according to the original German technology, which guarantees the silo shell tightness, exceptional strength, durability, reliability and allows to significantly accelerate the construction of the facility.

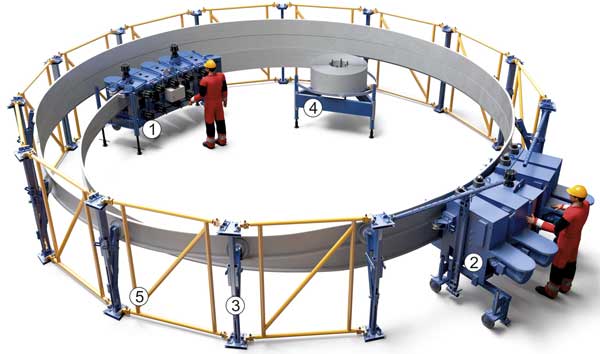

| 1. Forming machine | 4. Unwinder |

| 2. Rolling machine | 5.Crosspiece |

| 3. Supports |

Specifications:

| 1. Material | |

| – Galvanised steel | 2-4 mm |

| – Chrome-nickel steel | 2-3 mm |

| – Stainless steel | 1.5-2.5 mm |

| 2. Material width | 495 mm |

| 3. Finished silo diameter | 4.5-25 m |

| 4. Finished silo diameter | less than 31.5 m |

| 5. Maximum silo height to diameter ratio | 5.75 |

| 6. Production speed | linear speed: 5 m/min |

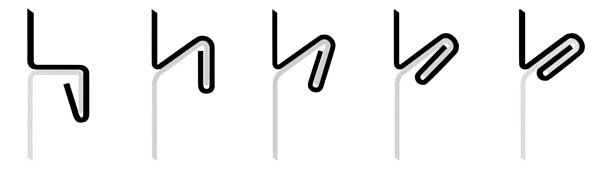

Schematic diagram of the double rolling of spiral silos

The main advantages of spiral silos manufactured using this technology are:

- low installation and investment costs – the silo is manufactured on site;

- high productivity – 5000 tonnes silo is assembled by 7 workers in 8-10 days;

- high durability;

- safety – for 40 years of silo construction using this technology, not a single case of collapse has been recorded.

- complete tightness