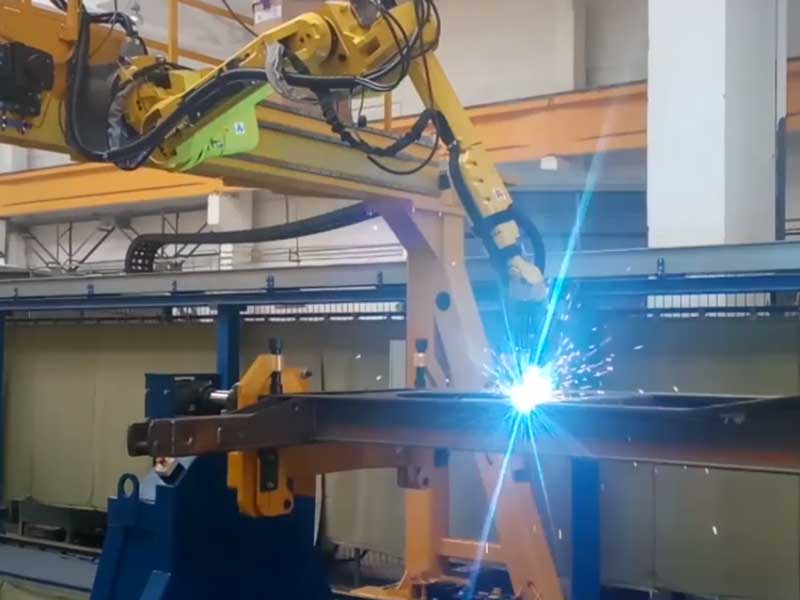

Robotic welding system facilitates a range of technological operations related to robotic welding of trailed vehicle assemblies.

Robotic welding system facilitates a range of technological operations related to robotic welding of trailed vehicle assemblies:

– two rotators for robotic welding;

– four adjustable changeable fixtures;

– a welding robot;

– a gantry complete with guide rails;

– robotic welding set with torch cleaning device;

– safety guard;

– electrical equipment.

Specifications:

| 1. | Welding robot | Fanuc |

| Welding robots, pcs. | 1 | |

| 2. | Rotators for robotic welding, pcs. | 2 |

| Carrying capacity, kg (max) | 4000 | |

| Rotator type | two-column | |

| 3. | Changeable fixture for robotic welding | |

| Quantity of changeable fixtures, pcs. | 4 | |

| Welding set for robotic welding with torch cleaning device | Fronius | |

| Type of welding | MIG/MAG | |

| Torch cooling system | liquid cooling | |

| Torch cleaning system | Robacta Reamer V Easy | |

| 4. | System to search for the product in space, track the trajectory of welds and adjust the parameters of welding modes | 1 pc. |

| Tracking system type | laser | |

| 5. | Overall dimensions of the station, mm | 32000х2500х2000 |

Safety

Laser barrier to protect staff

Prevents staff from entering potentially hazardous areas during machine operation. If the safety border is crossed, the barrier stops the machine operation

Barrier

The enclosure consists of a metal structure and curtains for protection against ultraviolet rays. Sensors are installed on the barrier to switch off the complex in case of human intrusion in order to exclude injuries to people.

SPTA kit

Extended SPTA kit for 12 months of operation

Includes a set of components which require regular replacement, providing minimum 12 months of operation.