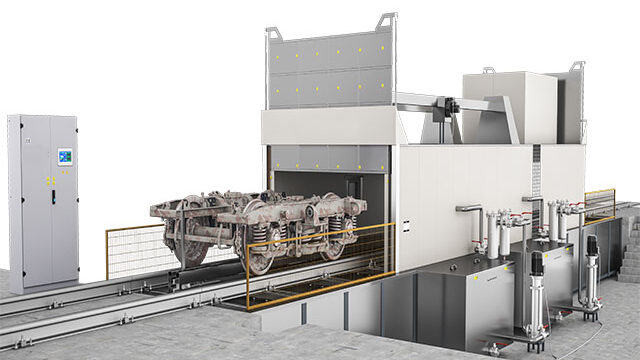

The automated station is designed for high-pressure washing of railcar bogie frames with heated detergent solution, followed by rinsing with hot water and drying.

The station operates as a conveyor line, moving bogies linearly through the washing chamber and processing them in sequential treatment stages:

– main washing;

– rinsing;

– bogie drying.

The conveyor is designed to transport freight wagon bogie frames into and out of the washing chamber. The conveyor system consists of a transport carriage, a drive unit, and a tensioning mechanism. The carriage moves along a rail track via an electric motor-driven cable. A rotating support is integrated into the bogie housing, onto which the dirty bogie frame is mounted.

The washing chamber is designed for cleaning bogie frames using detergent solution. The chamber body is made of stainless steel and insulated with thermal panels. The washing chamber is of the tunnel type. Washing is performed by a built-in spray system with specialized nozzle assemblies. There is a drip tray under the washing chamber for collecting the washing solution during the washing process. The washing solution heating tank and the rinse water tank are located separately in the washing chamber. The tanks and pipework are also made of stainless steel. Each tank is equipped with a digital thermostat with a selectable solution heating temperature of 90-95 ᵒC. The built-in time control of the washing cycle automatically maintains the workflow of cleaning the bogies. The doors of the washing chamber are hermetically sealed, allowing for a safe rinsing and cleaning process. The washing chamber is equipped with steam extraction nozzles, minimum/maximum solution level control and automatic water refill. The door lift drive is located on the roof of the chamber. The washing chamber operates both in autonomous and manual mode, is connected to the water supply system of the enterprise, has a closed circulation system for the washing solution and is replenished with water after the end of work or, if necessary, during operation.

The automatic control system of the station provides automatic operation of the main mechanisms: conveyor for moving the bogie, drives for lifting the washing chamber door, rotation of the bogie, rotation of the nozzle heads, start and stop of pumps, as well as control of each mechanism of the complex in the adjustment mode during commissioning, repair, preventive maintenance and in other necessary cases.

Operation principle

The dirty bogie is transported to the loading position and placed on the conveyor carriage in front of the washing chamber. After pressing the START button on the control panel, all mechanisms start working automatically. The bogie moves to the washing chamber via the cable conveyor. The door of the washing chamber closes. The bogie rotation drive is lowered and switched on, and the nozzle rotation drive is switched on. The high-pressure cleaning solution is fed through the rotating nozzle system onto the bogie, which rotates around its axis. The duration of the washing process is determined by a time relay.

After the set cleaning time has elapsed, the electric motors of the pumps and the nozzle rotation drive are switched off.

The door of the chamber opens, the bogie rolls out of the chamber with the help of the conveyor and stops at the unloading position after the washing chamber.

The washing cycle is complete and the system is ready to receive the next dirty bogie.

Technical characteristics:

| 1. | Time for washing bogies, min | 6-10 |

| 2. | Temperature of the washing solution, ⁰С | 40-95 |

| 3. | Heating of the washing solution | heating elements |

| 4. | Type of conveyor for moving bogies | cable |