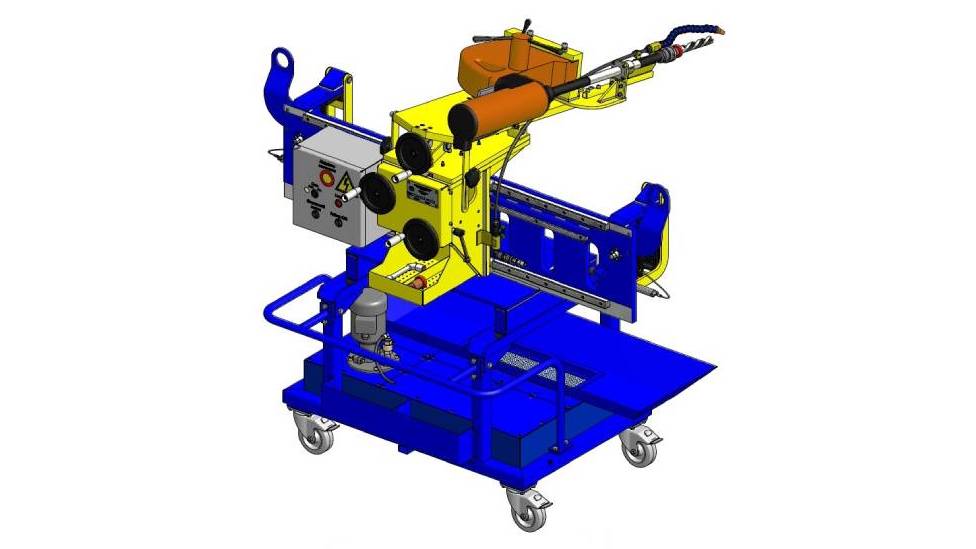

The drilling system is designed for precision machining of holes in the boiler supports and the frame of a tank wagon.

The design ensures reliable clamping and stability during operation, providing the required hole accuracy and surface finish.

System components are:

- drilling unit;

- coolant and chip collection unit.

Operating principle

The drilling unit is mounted on the tank wagon frame using a hydraulic stacker or an overhead crane. Once positioned, the unit is secured to the frame using special clamps tightened with a wrench. The system provides multi-tool machining of holes in a single setup, performing operations such as: drilling; countersinking and reaming (or drilling followed by reaming). A quick-change chuck enables rapid tool replacement, minimizing setup time. Cutting fluid (coolant) is supplied during machining to cool the cutting tools and remove chips. Power control is provided via an electrical control cabinet, while the control panel allows the operator to change spindle speed through the gearbox; smoothly adjust rotation speed, reverse spindle rotation direction, start and stop the main drive motor.

Technical specifications

| 1. | Maximum drill diameter, mm | 25 |

| 2. | Power, kW | 2000 |

| 3. | Stroke, mm | 145 |

| 4. | Total travel, mm | 258 |

| 5. | Feed mechanism | automatic |