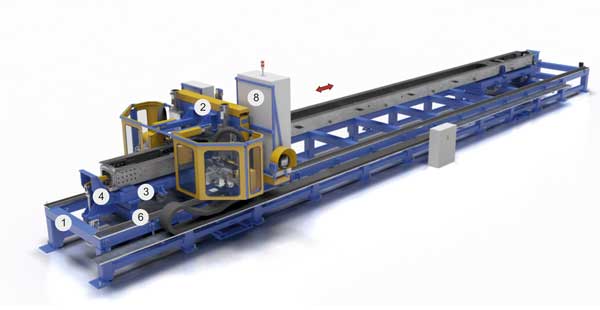

Automated drilling center is designed for performing of manufacturing operations connected with rivet holes drilling for freight cars center sills stops mounting.

| 1. frame | 5. clamps |

| 2. drilling gantry | 6. coolant tank |

| 3. supports | 7. air preparation unit |

| 4. rammers | 8. control system |

Advantages:

- complete machining per one operation;

- machining is performed automatically without preliminary marking;

- availability of chip removing conveyors provides high production standard, reduces time for stand cleaning.

- application of a moving gantry allows to reduce production floor space in comparison with the lines with a stationary drilling centers.