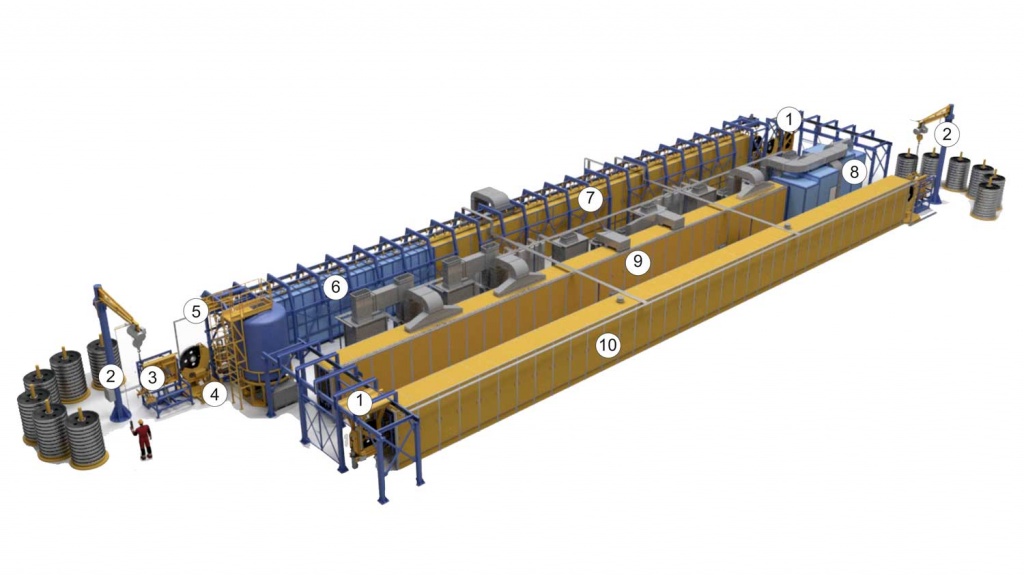

he line is intended for process operations on railroad wheels surface preparation and coating. The line is flexible and provides the coating of 5 standard sizes of wheels.

| 1. Transfer car | 6. Washing room |

| 2. Manipulator | 7. Drying booth |

| 3. Tipper | 8. Paint booth |

| 4. Quality Control Department inspection station | 9. Forced drying room |

| 5. Transportation system | 10. Annealing and cooling room |

Specifications

| 1. | Item specification: | |

| name | railway wheel | |

| diameter, m | 750, 850, 920, 1000, 1256 | |

| weight, kg | 223…1000 | |

| 2. | Productivity rate, pcs / h | 15 |

| 3. | Work schedule of the line | Two shifts, 24h, daily |

| 4. | Wheel position in the line | vertical |

| 5. | Coating method | Airless spray |

| 6. | Air pressure in pneumatic net, MPa | 0,7…0,8 |

| 7. | Air consumption, m³/h | 60 |

| 8. | Wheels preparation method prior to painting | water rinse |

| 9. | Circulating water volume, m³ | 3,40 |

| 10. | Mechanism of water supply to the wheel | pump, through nozzles |

| 11. | Wheel feed along the line | indexing |

| 12. | Installed capacity, KW | 835 |

| 13. | Overall dimensions, mm | 48900х14760х6245 |

| 14. | Weight, kg | 86230 |