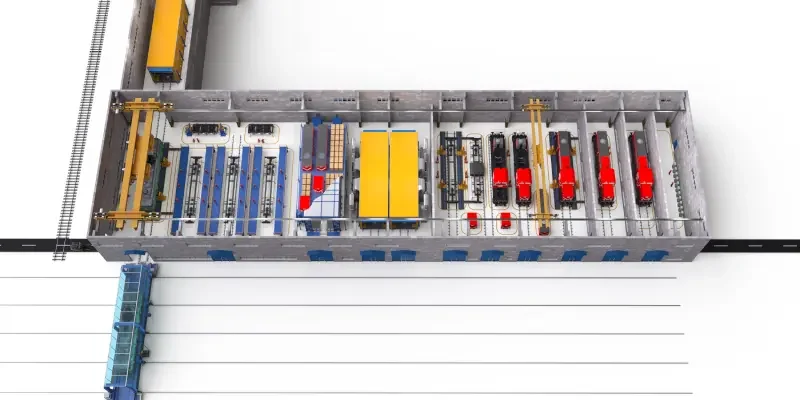

Techwagonmash offers comprehensive projects for the organization of production facilities for the modernization and repair of traction rolling stock (shunting and mainline diesel locomotives, electric locomotives)

Techwagonmash provides a full range of services: from the design stage to the stage of installation supervision and commissioning, including the production of special technological equipment.

Competencies of Techwagonmash

1. Pre-project elaborations;

2. Development of the technological part of the project;

3. Design of special technological equipment;

4. Manufacture of special technological equipment;

5. Installation supervision and commissioning: personnel training;

6. Staff training;

7.Practice technology;

8. Customer service.

Advantages of upgraded locomotives

As a result of modernization, the technical and economic performance of the locomotive is improving.

Its efficiency and traction parameters are significantly increased:

– fuel consumption is reduced by about 20-25% (for example, TEM2 is 450,000 dollars. US$ per life cycle);

– reduction of repair and maintenance costs by 25-30% (for example, for TEM2 it is $ 360,000. US$ per life cycle);

– by increasing the coefficient of technical readiness, it is possible to reduce the number of diesel locomotives at the enterprise.

The updated locomotive is equipped with microprocessor control, monitoring and self-diagnosis systems, such modernization increases the reliability of the locomotive, increases inter-repair runs, reduces the cost of scheduled and emergency repairs