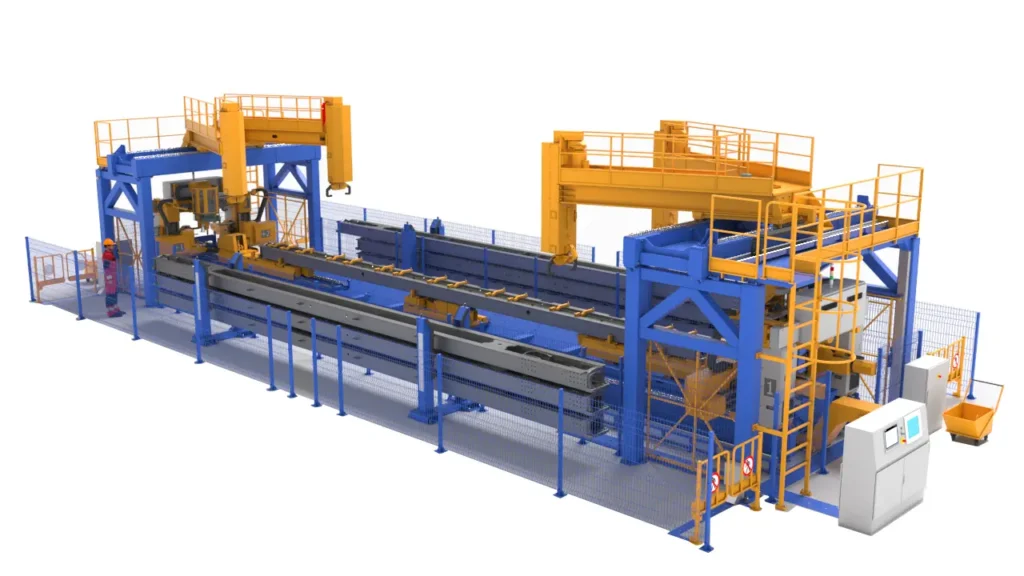

Equipment Name: Automated CNC Drilling Stand for Freight Wagon and Hopper Center Sills

Customer: JSC Tikhvin Freight Car Building Plant

Year of Implementation: 2015

Machining Time for One Center Sill with Two Gantries: 23 Minutes

Techwagonmash has successfully developed and commissioned a high-performance CNC drilling stand for machining center sills of freight wagons and hopper cars.

The system’s innovative design and advanced automation ensure exceptional precision, productivity, and safety in metal structure manufacturing.

Purpose and Application

The stand is designed for high-efficiency mechanical drilling of holes in center sills of freight wagons and hoppers using axial tools in two perpendicular planes within a single setup.

A major advantage is the elimination of manual marking and drilling jigs — all operations are fully automated under CNC control.

The stand performs drilling of:

- rivet holes for stops and bearing plates,

- holes for wear-resistant plates,

- technological openings,

- mounting holes for brackets and brake equipment components.

Design and Operating Principle

The machine is built around a clamping table, serving as the base of the entire structure.

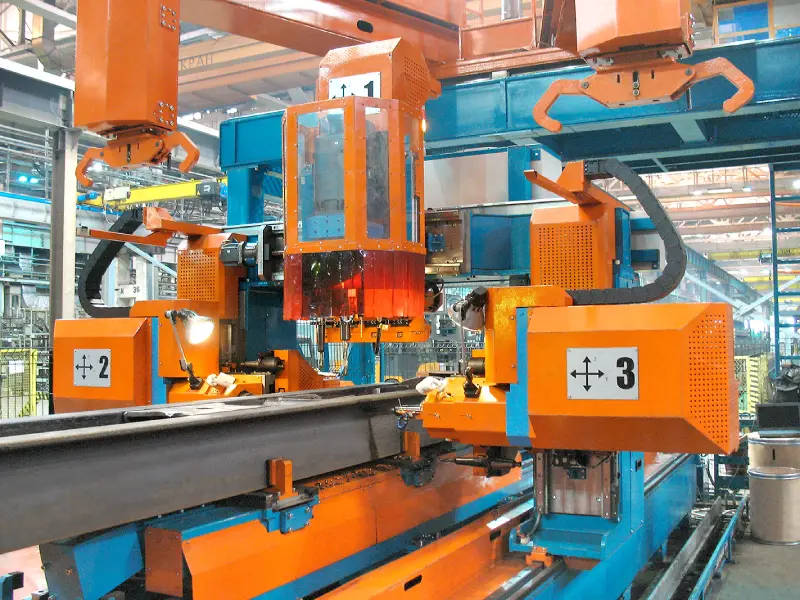

Two independent drilling gantries move along precision guides and can operate either simultaneously or separately, depending on the machining program.

Each gantry includes:

- a vertical drilling head mounted on a crossbeam,

- two horizontal drilling heads on vertical supports.

Together, these three heads allow simultaneous machining from the top and both sides of the beam.

Key technical features:

- CNC control for precise motion and automatic positioning;

- Contact probe for exact beam measurement before drilling;

- MQL (Minimum Quantity Lubrication) system for external tool cooling with minimal lubricant use;

- Centralized lubrication system for reduced maintenance effort;

- Automatic tool changers (4 tools per head) for flexibility in beam size adjustment.

To maintain cleanliness and continuous operation, two chip conveyors located beneath the table collect and transport metal chips into four chip carts — two per conveyor.

Automated Loading and Unloading

The stand’s productivity is significantly increased through dual automatic loading and unloading systems.

These devices work synchronously, transferring beams between the loading and unloading racks, which minimizes downtime between machining cycles.

The system includes:

- telescopic lifters with pneumatic grippers;

- motorized trolleys on guide rails;

- safety locks to prevent unauthorized manipulator extension;

- three-level storage racks for raw and finished beams.

Safety and Monitoring

The entire work area is divided into three safety zones:

- Drilling zone,

- Loading zone,

- Unloading zone.

Each zone is equipped with electromagnetic gates and turnstiles that restrict access during operation.

A video surveillance system with six cameras allows the operator to monitor all processes remotely from the control console.

Additionally, signal light towers indicate the operational status of each gantry, ensuring clear visual feedback.

Control and Automation

The stand is fully operated from a touchscreen control panel.

The monitor displays real-time video feeds, machining parameters, and system diagnostics.

The control software allows the operator to:

- select beam types and machining programs;

- automatically readjust clamping systems for different beam lengths;

- manage the entire drilling cycle from loading to unloading without manual intervention.

Project Advantages

- Full automation of drilling and material handling processes;

- High machining accuracy through CNC control and contact probing;

- Reduced cycle time and increased productivity;

- Lower maintenance costs thanks to centralized lubrication and MQL;

- Enhanced operator safety and ergonomics via intelligent zone management and visual monitoring.