Equipment Name: Automatic Welding Stand for Spine Beam with I-Beam

Customer: JSC Tikhvin Freight Car Building Plant

Year of Implementation: 2015

System Capacity: up to 2.5 beams per hour

Description and Operating Principle

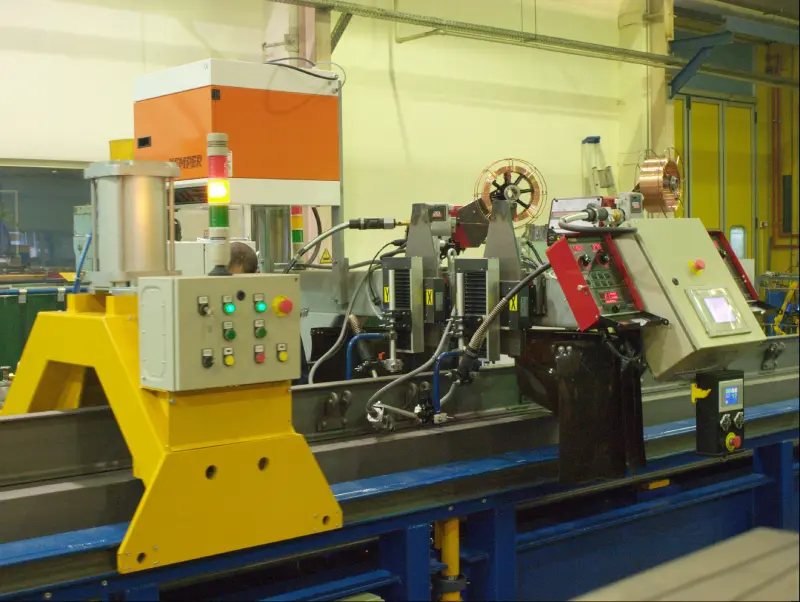

The automatic welding stand for spine beams with I-beams is a high-tech equipment complex designed for assembly, tack welding, and full welding of an I-beam to a spine beam in a fully automated mode.

The system is equipped with an electromechanical tracking system that ensures precise positioning and consistently high weld quality.

The installation includes:

- main stand with beam fixation system;

- transport system;

- welding trolleys for moving welding units and power sources;

- gantry-type trolley;

- pneumatic cabinet;

- electrical and control equipment.

Technological Process

- Preparation and Fixation. The spine beam is placed and securely fixed in the stand.

- I-Beam Installation. The manipulator positions the I-beam onto the spine beam, and the system initiates the operating cycle.

- Centering and Tack Welding. The trolley moves along the stand, performing precise centering and vertical clamping of the I-beam. A following welding unit performs tack welds.

- Main Welding. After tack welding is completed, two welding units simultaneously perform the main welding process:

- the first unit welds from the beginning of the beam to the midpoint;

- the second — from the midpoint to the end.

This dual operation reduces welding time by half and minimizes thermal deformation.

- Cycle Completion. Upon completion, the trolleys and welding units automatically return to their initial positions. All operations are performed in a fully automated mode without operator intervention.

Advantages of the Welding Complex

- Fully automated welding process;

- High assembly accuracy and geometric stability;

- Up to 50% reduction in welding time;

- Minimal deformation of welded structures;

- Increased productivity and consistent weld quality.