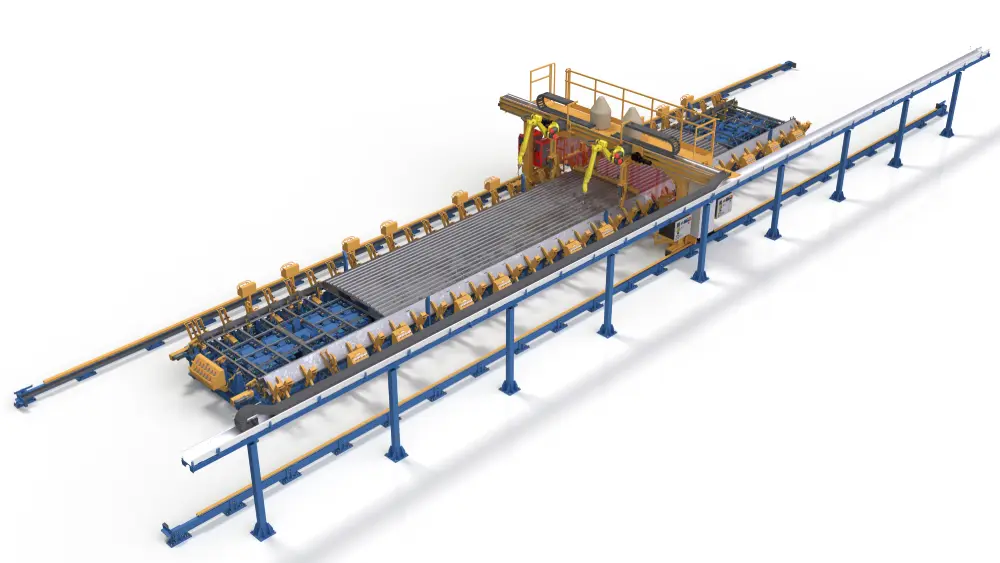

Equipment name: Robotic assembly and welding complex for metro car roofs

Customer: Metrowagonmash

Year of implementation: 2019

In modern metro car manufacturing, automation plays a key role in improving efficiency and quality. The robotic assembly and welding complex for metro car roofs is designed to optimize manufacturing processes, ensuring high precision and reliability. If you are looking for advanced technologies for welding and assembling metal structures, this complex is the ideal choice for your enterprise.

Purpose of the Complex

The robotic assembly and welding complex for metro car roofs is specifically developed for automated assembly and welding operations. It enables the production of roofs for two different metro car models thanks to its reconfigurable design. To adapt to various roof frame types, the complex is equipped with interchangeable jigs, providing flexibility and minimizing downtime in production. This solution is perfect for factories manufacturing components for public transportation, such as metro systems, where high-precision MIG/MAG welding is required.

Operating Principle

The complex operation begins with placing roof frame components onto the support surfaces of the assembly stand using shop overhead handling equipment. The parts are aligned against stops, after which workers perform tack welding of the positioned elements.

The gantry with robots then moves from the standby zone to the roof assembly stand and stops above the roof. Moving along the gantry, the robots weld the roof frame in the reachable section. The gantry advances step-by-step, allowing the robots to weld the frame section by section.

Before welding each seam, the robot uses a laser tracking system to verify the exact seam position based on reference points. This enables correction of the torch path in the welding program, ensuring flawless weld quality without defects.

After frame welding, side and top skin sheets are placed on the frame and secured with stand clamps. Workers tack weld the sheets to each other and to the frame. Roof skin welding is performed in transverse and longitudinal directions:

- The gantry moves to the assembly stand, and robots weld the skin to the frame arcs.

- Pneumatic clamps on the gantry press the skin against the frame arcs at weld locations, while the pressure roller ensures longitudinal fixation.

- The process concludes with MIG/MAG welding of longitudinal skin seams.

Upon completion of roof welding, the gantry with robots automatically returns to the standby zone. The finished roof is released from clamps and fixtures, removed from the stand, and transported to the position for finish welding on the reverse side.

This operating principle minimizes manual labor, accelerates metro car roof production, and enhances workplace safety.

Control System

The robotic complex is controlled from a panel using touch screens and dedicated buttons. The operator selects the operating program based on the metro car roof model, enabling quick system reconfiguration. Control systems are built on Siemens programmable logic controllers, ensuring reliability, user-friendliness, and seamless integration with other production lines.

If you are interested in implementing robotic complexes for welding and assembly in your metro car manufacturing, this system offers the optimal combination of MIG/MAG welding technologies, automation, and flexibility. Contact us for implementation consultation!