Equipment name: Robotic System for Assembly and Welding of Gondola Car End Walls

Customer: LLP “Kazakhstan Wagon Building Company”

Purpose of the Equipment

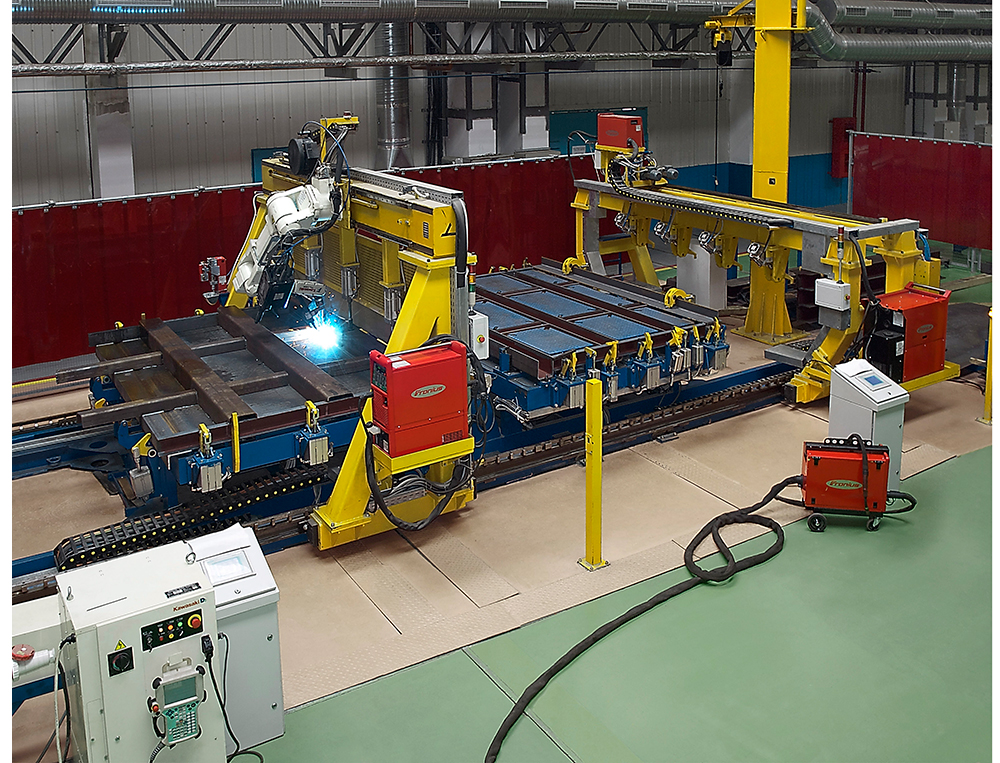

In modern railcar manufacturing, process automation plays a key role in improving efficiency and quality. The robotic gondola car end wall assembly and welding system is a high-tech solution designed to optimize assembly and welding operations. This system ensures precise assembly and automated welding of end walls in the reverse position, as well as robotic arc welding in the normal position.

Design and Configuration

The system represents a modern robotic stand that integrates all equipment required for assembling and welding the end wall components in different positions. The complex includes:

- Assembly and welding stand for the end wall in reverse position;

- Welding stand for the end wall in normal position;

- Manipulator for 180° rotation of the welded structure;

- Automatic welding portal for joining the outer sheets with the frame;

- Robotic welding portal for the end wall in normal position;

- A set of supports, pneumatic and electrical equipment.

The working area of the complex is enclosed on three sides by a robust metal fence made of rectangular tubes and mesh panels. The fencing is fixed to the shop floor using wedge anchors.

To ensure operational safety during robotic welding, the system is equipped with light barriers (emitter and reflector) that automatically block the robot’s operation if the light beam is crossed.

Operating Principle

- The end wall components are placed on the assembly and welding stand in reverse position according to the technological process.

- The elements are positioned, tacked, and covered with outer sheets.

- The portal performs welding of four overlapping seams.

- Using the manipulator, the end wall is rotated 180° and placed on the welding stand in the normal position.

- After fixation, final robotic welding of the gondola car end wall is performed.

Advantages of the Robotic System

- High precision of welded joints;

- Reduced production cycle time;

- Minimal human involvement;

- Consistently high product quality;

- Enhanced operational safety and convenience.