Equipment Name: Railway wheels painting line

Customer: Interpipe NTZ

Since 2016, Interpipe has been manufacturing railway wheels and wheelsets for high-speed trains — a product with high added value. This type of product is in strong demand in the transport infrastructure of Europe and the Americas, which prompted the company to make significant investments in launching several new production sections, including facilities for applying operational and anti-corrosion coatings to railway wheels.

The design and manufacture of equipment for these coating application sections was carried out by the TECHVAGONMASH.

As a result, TECHVAGONMASH specialists created the first semi-automatic coating line in Ukraine for applying operational and anti-corrosion coatings to railway wheels. Despite its short operating period, the line has already received positive feedback from the customer. It provides high-quality coating application across the entire range of wheels produced by the plant.

One of the key development areas has been the introduction of coating stations for performance and anti-corrosion coatings on railway wheels. This technology significantly increases the service life of wheels, improves their resistance to external influences, and complies with international standards for railway operation.

Creation of the first coating line in Ukraine

The design and manufacture of equipment for the new production stations was entrusted to the company TECHVAGONMASH, which has extensive experience in developing and implementing technologies for the railway industry.

As a result of the joint work of specialists from Interpipe and Techvagonmash, the first semi-automated line in Ukraine for applying performance and anti-corrosion coatings to railway wheels was created.

In the first few months of operation, the line demonstrated excellent results and received positive customer feedback. The equipment ensures high precision surface preparation, uniform coating application, and stable process parameters at all stages of the production process.

Wilckens SEB 9303 Coating Technology

A key feature of the line is the ability to apply Wilckens SEB 9303 operational coating, which serves as an overheating indicator for wheel surfaces. This coating provides visual evidence of thermal overload:

- at 220–230 °C, the coating changes color,

- at 250–300 °C, it begins to blister,

alerting maintenance personnel to the need for wheelset replacement and preventing potential safety hazards.

The equipment was engineered in strict accordance with Interpipe’s technological specifications, ensuring precise adherence to all parameters required for correct application and curing of this sophisticated coating.

The control system monitors and regulates each step of the process—from initial surface preparation to final drying and cooling.

Technical Advantages of the Coating Line

The equipment developed by Teсhvagonmash meets the highest quality standards for surface preparation and coating application.

The automated control system provides:

- accurate dosing of solutions and feed to spray nozzles;

- constant monitoring and maintenance of water and solution levels in process tanks;

- protection of pumping systems from dry running and overflow;

- temperature and airflow regulation within washing, drying, and coating chambers;

- stable coating application and curing parameters.

This high level of automation ensures exceptional coating quality, fully compliant with Interpipe’s requirements and international railway industry standards.

Versatility and Adaptability

During the design phase, Teсhvagonmash specialists ensured that the equipment could also apply water-borne and solvent-based coating materials.

This enhances operational flexibility and makes the line suitable for meeting diverse customer requirements in both domestic and international markets.

As a result, Interpipe gains the ability to respond quickly to customer demands, broaden its product portfolio, and strengthen its competitive position globally.

Structure and Components of the Coating Line

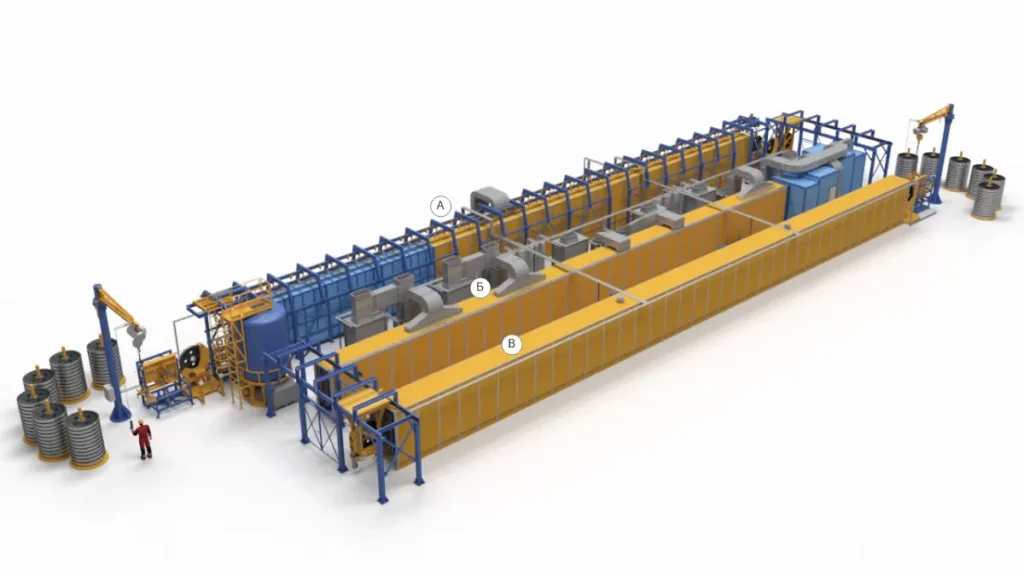

The semi-automatic coating line consists of three main technological sections:

Section A — Surface Preparation

Includes the loading equipment, manipulators, tilting units, incoming inspection station, washing and degreasing chambers, drying and cooling modules, and a dedicated transport system. This section provides complete mechanical and chemical surface preparation, essential for proper coating adhesion.

Section B — Coating Application and Drying

This area includes painting chambers, normalization chambers, and active drying units (thermo-radiation–convective and convective).

A specialized transport system moves each wheel through all stages of coating, curing, and heat treatment.

Section C — Cooling and Quality Control

After coating and drying, wheels enter cooling, holding, and final inspection.

Each wheel receives a barcode label to ensure full traceability throughout its operational life cycle.

Safety and Automation

The line features a comprehensive control and safety system designed to prevent unauthorized equipment activation and eliminate risks of mechanical damage or operator injury.

A centralized ventilation and air-exchange system is installed above all chambers, maintaining stable air parameters and ensuring safe working conditions in painting and drying zones.

Production Specifications

- Wheel diameter range: 700–1350 mm

- Line capacity: up to 15 wheels per hour

- Operating staff per shift: 8 employees (7 operators and 1 supervisor)

Thanks to advanced automation, operator involvement is minimized, ensuring stable, repeatable, and safe coating processes.

Implementation Results and Future Prospects

The launch of the semi-automatic coating line represents a major milestone in the modernization of Ukraine’s railway engineering industry.

The technology developed by Teсhvagonmash and implemented by Interpipe provides:

- increased durability and reliability of railway wheels;

- improved performance and wear resistance;

- compliance with global safety and environmental standards;

- reduced maintenance costs for rolling stock operators.

With this innovation, Ukraine now hosts a world-class industrial facility, capable of meeting the demands of both domestic and international customers in the railway components market.

Conclusion

The collaboration between Interpipe and Teсhvagonmash has resulted in a landmark project—the development of Ukraine’s first semi-automatic operational and anti-corrosion coating line for railway wheels.

This cutting-edge solution combines advanced engineering, modern production technologies, and high safety standards. The line sets a new benchmark for quality in railway wheel manufacturing and strengthens Ukraine’s presence in the global railway supply chain.