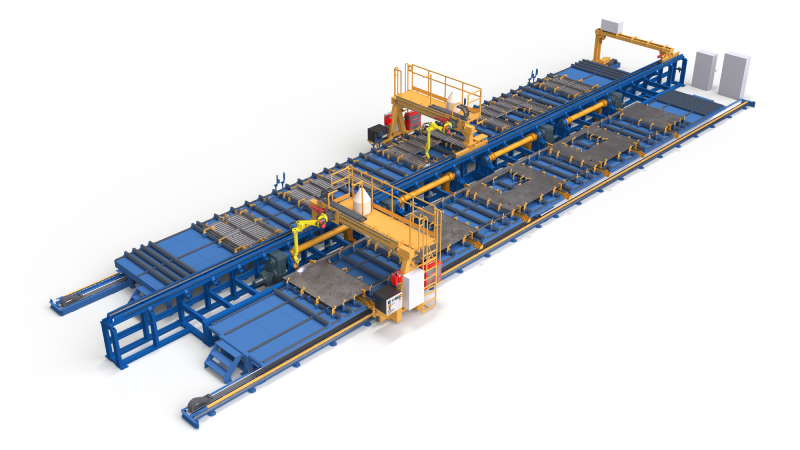

Equipment name: Robotic Assembly and Welding Complex for Metro Railcar Sidewalls

Customer: CJSC “Metrovagonmash”

Year of implementation: 2019

Complex productivity: 1,050 units/year

The developed complex is designed to automate technological operations for assembly and welding of large-size sidewall panels of metro railcar bodies, meeting high requirements for geometric accuracy, weld quality, and repeatability of product parameters. The implementation of robotic technologies has significantly increased the productivity of the production area and ensured stable quality of the manufactured products.

The complex includes:

- assembly and welding fixtures with positioning and clamping systems for sidewall elements;

- industrial welding robots with CNC control;

- automated positioning and equipment synchronization systems;

- process control system with the ability to adapt welding modes to specific products;

- systems for monitoring geometric parameters and weld quality.

The project was implemented on a turnkey basis — from development of design documentation and technological solutions to manufacturing, assembly, commissioning, and commissioning into industrial operation at the customer’s production site.

As a result of implementing the robotic complex, CJSC “Metrovagonmash” received a modern high-efficiency solution that ensures:

- improved accuracy of sidewall assembly;

- enhanced quality of welded joints;

- reduced influence of the human factor;

- increased productivity and stability of the production process.

The implementation of this project confirmed the competencies of Techvagonmash in the field of designing and manufacturing automated and robotic technological complexes for transport engineering enterprises.