Equipment name: Integrated automated line for weighing, length measurement, stamping and marking of pipes

Customer: INTERPIPE NIKO TUBE LLC

Year of implementation: 2018

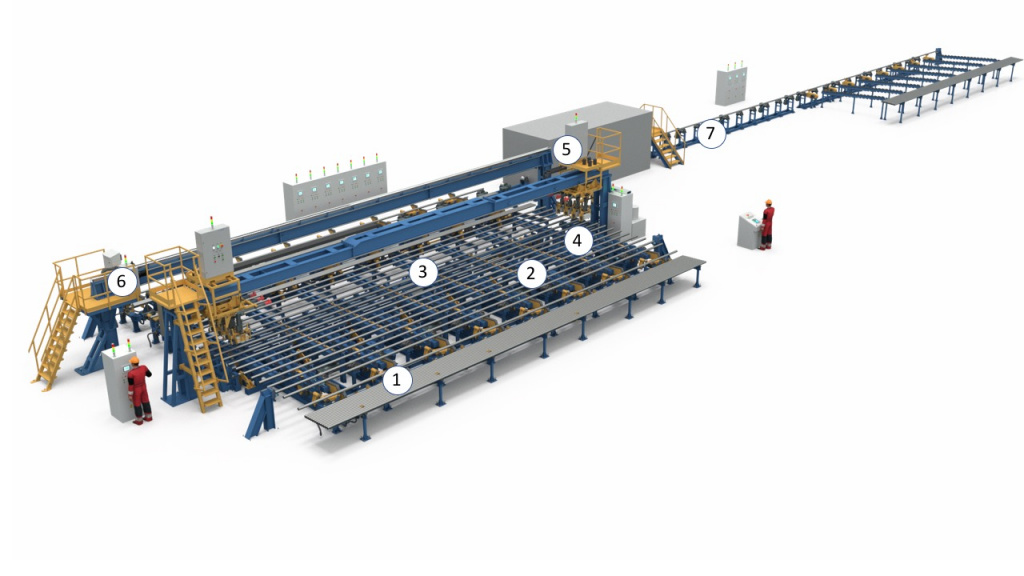

In 2018, Research and Production Company “Techvagonmash” implemented a project for Interpipe to create an integrated automated line for weighing, length measurement, stamping and marking of pipes, designed for operation in an industrial pipe production environment.

The developed system ensures fully automatic execution of pipe inspection and identification operations without operator involvement, providing high measurement accuracy and stable marking quality.

Functional capabilities of the line:

- integration into the existing production and information infrastructure of the enterprise;

- automatic pipe weighing;

- high-precision length measurement;

- application of identification stamping;

- pipe marking in accordance with customer requirements and quality standards;

Technical solution description

The implemented line consists of transport mechanization systems and a set of specialized equipment, including:

- gravity roller table with transfer devices for uniform feeding of pipes into the process flow;

- static weighing scales for products;

- portals for stamping and longitudinal marking with digital data recording;

- a control system based on a SIEMENS PLC with a human-machine interface (HMI) panel, ensuring stable operation and collection of process data.

The control system provides data acquisition, processing and transmission, as well as safe operation of the line. All modules are controlled via a central control panel, allowing flexible adaptation of the system to pipe dimensions, geometry and specifications.

Project results

The implementation of the line enabled Interpipe to significantly improve the efficiency and quality of final pipe processing before shipment, as well as to ensure transparent product control at critical stages of the technological cycle. The system is among the key innovative solutions at the enterprise and confirms the competencies of Research and Production Company “Techvagonmash” in the field of metallurgical production automation.