Imagine a paint shop — spacious, bright, and ergonomically designed. At first glance, it seems simple: draw up a layout, buy the equipment, install it, and start making money. But what’s the most important thing to start with? Of course — the spray booth!

All spray and drying booths look similar from the outside: a cabin with bright lighting, a heating system, and ventilation. However, choosing the right booth is not that simple — it’s the most expensive piece of equipment in the shop, and mistakes can be costly. In this article, we’ll explain complex things in simple terms, using the spray and drying booths manufactured by Techvagonmash as an example.

How to Choose a Spray Booth

When selecting such an expensive piece of equipment, it’s essential to consider quality, productivity, reliability, and cost-efficiency — all balanced with a reasonable price.

- Quality — Ensures flawless painting results.

- Productivity — Maximizes time and space efficiency, allowing more parts to be painted per cycle and more cycles per shift.

- Reliability — Depends on a well-thought-out design, build quality, and durable components, ensuring long service life with proper maintenance.

- Cost-efficiency — Affects operational costs. Frequent maintenance and downtime reduce shop output and profitability, just like fuel consumption and service costs affect the total cost of owning a car.

How a Spray Booth Works

The operating principle is generally the same across all models:

- Painting Mode:

Fresh air is drawn in from outside, passes through a coarse filter in the air handling unit, and is heated to about 20°C in a heat exchanger. It’s then cleaned using fine filters before entering the booth. An exhaust fan continuously removes used air, maintaining clean airflow. - Drying Mode:

The booth switches modes: first, it performs a purge to remove solvent vapors, then switches to recirculation mode. The fan stops, and air circulates inside the cabin. The burner heats the air up to 60°C, maintaining the temperature automatically. Energy consumption depends heavily on the heat exchanger’s efficiency. To prevent solvent vapor buildup, 10% fresh air is constantly supplied.

Key Factors for High-Quality Painting

To achieve perfect results, you need:

- Dust-free conditions

- Stable temperature control

- Even airflow distribution

Modern paints require precise control of air parameters so that multiple colors can be sprayed in a single cycle, improving shop efficiency. Let’s review the essential components.

Plenum Chamber

The plenum is the “attic” of the booth, where air is distributed before entering the cabin. A taller plenum (70 cm vs. 50 cm in competing models) ensures even airflow, even with powerful ventilation systems. Air passes through fine filters that trap particles as small as 50 microns (about the size of cigarette smoke) before reaching the cabin.

Ceiling Design

Ceiling structure significantly affects airflow uniformity.

- In many booths, lights are installed at an angle, reducing filter surface area and disrupting laminar flow.

- In Techvagonmash booths, lights are built into the walls, preserving the full filter area equal to the cabin floor.

Ceiling filter replacement takes less than an hour and can be handled by one operator, minimizing downtime.

Floor and Pit Design

A full-size pit and grated floor ensure that overspray and dust settle into the floor filters, preventing contamination when switching between painting and drying. Smaller pits used by some competitors create air turbulence, increasing the risk of dust landing on freshly painted surfaces. Techvagonmash uses full-size pits and gratings for stable airflow.

Gratings

Gratings must be strong enough to support heavy parts but light enough for easy handling. Techvagonmash gratings can be lifted by one person, and filter replacement takes under an hour.

Booth Structure

A rigid frame design withstands internal pressure fluctuations when switching modes, ensuring durability and dust protection.

Booths are made of a steel frame and sandwich panels (galvanized steel with non-combustible insulation), providing excellent thermal insulation and structural strength.

Heat Exchanger

Techvagonmash heat exchangers feature thicker walls and high thermal capacity, ensuring stable temperatures even in cold climates (down to -20°C). Unlike lighter Italian models designed for warmer regions, these units are more expensive upfront but save up to 30% in fuel costs, paying for themselves over time.

Energy-Saving Options

- IRS System — Switches the booth into recirculation mode when the spray gun isn’t in use, saving energy during pauses (especially when using water-based paints).

- Variable Frequency Drives — Adjust fan speed based on workload, reducing fuel consumption.

- Gradual Heating — Raises temperature step by step (45–47°C → 50°C → 60–65°C) over 8–9 minutes instead of 3, improving paint quality (especially with water-based paints) without significant extra fuel use.

Fuel Options

Spray booths can run on:

- Natural gas

- Diesel

- Electricity

In many regions, diesel is more cost-effective due to high gasification costs and bureaucratic hurdles.

Additional Options

- Carbon Filters — Reduce solvent emissions, essential for shops near residential or protected environmental zones.

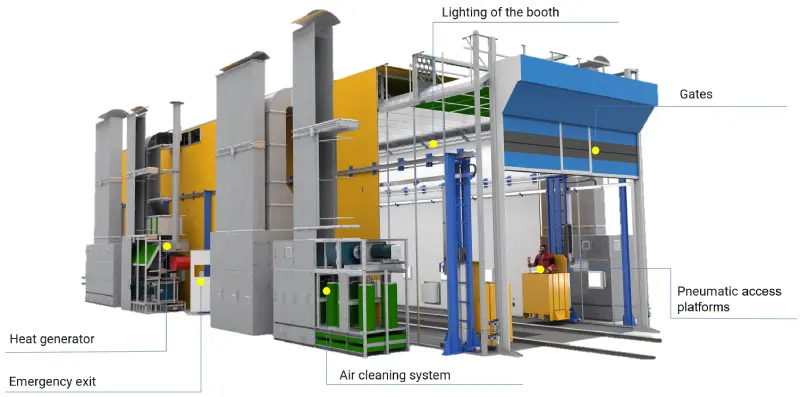

- Pneumatic Lift Platforms — Allow operators to easily reach all areas of large workpieces safely and comfortably.

- Fire Suppression & Solvent Vapor Control Systems — Improve drying speed and safety, especially with water-based coatings.

- Transport Trolleys — Simplify handling, improving both efficiency and operator comfort.

An Investment in the Future

A spray booth isn’t just an expense — it’s an investment. It’s not only about asking, “How much does it cost?” but also, “How much will it earn me?”

Choosing the right spray and drying booth ensures high productivity, excellent quality, and greater profitability for your paint shop.