There is a persistent stereotype in the post-Soviet machine-building industry that industrial robots are expensive equipment that requires highly professional personnel and that it is rational to use them in mass or high-volume production. This myth is based on some factors listed below.

Factor 1. When calculating the efficiency of robotic workcell (RWC) implementation, often only the direct piece wage of the welder is considered, but the following factors are omitted:

· direct and indirect taxes on basic payroll (BP);

· additional pay;

– expenses for maintenance of facilities;

· coefficient that takes into account the possibility of uninterrupted operation of RWC due to the absence of shift work, holidays, sick leave, and unproductive losses;

· reduced costs for welding consumables (wire, shielding gas) and electricity;

· reduction of labour intensity when cleaning weld seams;

· elimination of costs for training and recertification of qualified welders.

Table 1 provides a list of the costs mentioned above and other expenses.

Table 1. Illustrative list of items of expenditure

| 1. | Group and cost item | |

| Maintenance materials | ||

| Transport and procurement costs | ||

| 2. | Expenses for maintenance and operation of buildings: | |

| Salary of service personnel | ||

| Payroll deductions | ||

| Materials | ||

| Heating | ||

| Electricity | ||

| Wastewater and stormwater drainage | ||

| Use of drinking water | ||

| Water heating | ||

| Expenditure on letterheads and stationery | ||

| Depreciation and amortisation of buildings | ||

| Depreciation of household equipment | ||

| 3. | Occupational safety | |

| Materials (special clothing and personal protective equipment) | ||

| Contracts to third-party service organisations | ||

| Special nutrition (milk) | ||

| 4. | Repair fund | |

| energy sources (materials) | ||

| Mechanical aid (materials) | ||

| Materials for buildings | ||

| Salary (fitters – repairmen, electricians and electricians) | ||

| Payroll deductions | ||

| Contracts for equipment repair, services of third-party organisations | ||

| Total material costs | ||

| Piece rate | ||

| Additional salary (54%) | ||

| Social insurance contributions (38,57%) | ||

| Total labour costs: |

The items of costs and expenses in Table 1 are rather conventional and have different indicators for each enterprise.

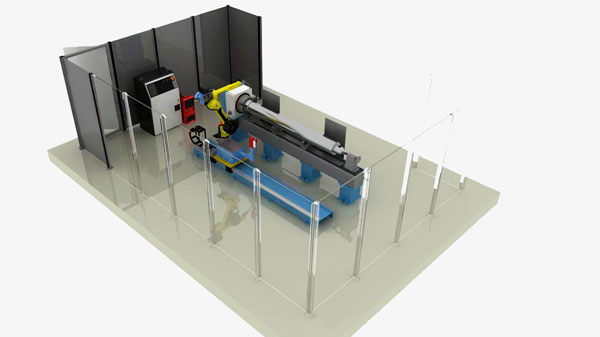

Fig. 1. RWC with two-axis rotator.

Factor 2. The company personnel is unwilling and unable to understand new technological processes. As a result, it is necessary to attract new specialists, which jeopardizes the return on investment and causes contradictions in the team. Besides, it should be mentioned that it is problematic to engage an RWC operator-programmer with the proper level of training in the project.

Factor 3. Robotic welding is intended for large production volumes, e.g. series production of automobiles. However, the model range should not change over many years. Most managers believe their companies produce batches that are not big enough to justify investing in a robotic system (insufficient RWC flexibility).

Fig. 2. RWC with two-axis rotator.

Factor 4. Robotic complexes often break down, their repair is expensive and time-consuming. Qualified specialists for their repair and maintenance are hard to find.

Now let’s look at how the above problems play out.

On Factor 1. We suggest that you perform your calculation of the cost-effectiveness of RWC implementation. The recommendation is the following: the initial data should reflect real values and not be “pulled by the ears”. As a result, you will get a return on investment time and will be able to make an informed decision.

On Factor 2. Since the advent of welding robots, manufacturers have been constantly improving the process of writing work programs to simplify it as much as possible and thus make the life of the operator-programmer easier. Today, this problem has been solved with the brand new Kinetiq robot training program developed by Robotiq (Canada). This technology allows the operator to move the robot’s welding torch along the entire weld line by hand, and then use the remote control to enter the motion trajectory into the memory and determine the welding parameters. Other developers also offer similar programs.

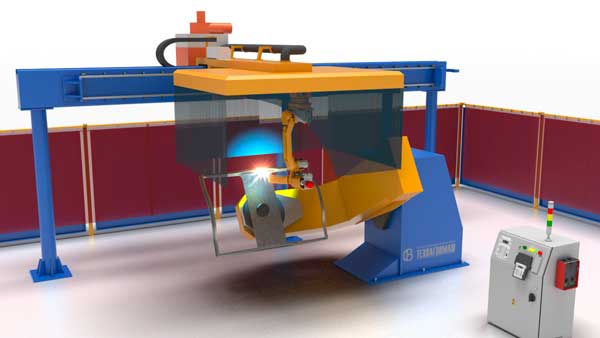

Fig. 3. RWC with gantry unit and two tilting assembly stands.

On Factor 3. Modern RWCs are multifunctional and are capable of rapid tool changes in automatic mode. For this purpose, the RWC must be surrounded by various interchangeable tools. The tool sockets are designed for quick tool changes. The robot can be programmed to work all day in only one position with a specific set of tools, or in multiple positions, producing small batches of each part.

The operator only needs a few movements to completely change from one set to another. The robot stores many different programs in its memory and it is only necessary to switch the program to start welding a completely different part.

You do not need to select the RWC configuration and equipment yourself. You need to correctly draw up a technical specification for the required complex and address it to the specialists.

Рис. 4. РТК потолочного базирования с двумя дополнительными осями и вращателем

On Factor 4. Modern RWCs are usually equipped with a USB output, which allows programs created by offline programming to be transferred to the robot’s memory. In addition, Internet connectivity is available for online communication with the supplier providing warranty or post-warranty support. As practice shows, 99% of complex failures occur due to the error of the operator or RWC programmer (incorrectly installed in the RWC part, poor quality assembly for welding, error in program creation, etc.). These errors are easily diagnosed and eliminated on-site. The remaining 1% is a program failure. Diagnostics and elimination of errors are performed remotely without loss of time. In rare cases, the integrator’s specialist needs to visit the site. Here the decisive factor is geographical remoteness and supplier’s commitment. The conditions of warranty or post-warranty service should be taken into account in the supply contract.

Fig. 5. Gantry RWC for welding roof-type products.

A few more arguments in favor of RWC’s effectiveness.

Increased productivity. One of the main ways to justify the cost of a robot is to compare the productivity of an RWC to the productivity you currently have with manual or semi-automatic welding. In many cases, robotic welding is 2-5 times faster than any other method. This means that for every hour you produce 2-5 times more parts than you are currently producing. For example, a MIG tandem welding system that simultaneously uses two arcs joined by a robot can increase productivity many times over.

High reliability. Implementing RWC in production can relieve shop floor workload, reduce labor requirements, and make production more profitable Robots are reliable, they can work around the clock, without rest or lunch breaks. Plus, with robots, you’ll forget about employee turnover. They are loyal to your company and will not leave after you train them.

There are also social aspects: robots can be used in hazardous areas of production (cleaning welds, for example), preserving the health of workers.

Opportunity to increase volumes. When you sign a new contract or want to expand the range of work you do, robots can handle the extra volume with ease. The workspace occupied by an RWC is more compact than a manual work area. As production expands, you won’t have to worry about new buildings, renting, or buying additional space.

Guaranteed quality. The high positioning accuracy of industrial robots, the consistency of speed, and the precise repeatability of operations ensure reliable product quality and eliminate the possibility of producing defects. With robots, the company invests in the product up front, without having to correct defects after they occur, as is often the case with manual or semi-automatic welding.

For robot welds, visual inspection is usually sufficient. In the case of semi-automatic or manual welding, additional tests such as selective destructive testing, radiography, or dye penetration inspection may be necessary.

Fig. 6. RWC with additional axis and two double-column rotators.

Savings on welding consumables. Manual welding consumes more filler material, as it is difficult for the welder to perfectly maintain the required cross-section and strength margin of the weld. The precision of the work is much higher: the dosed amount of filler material is programmed. In addition, robotic welding results in less spatter and, as a consequence, 10-15 % lower welding wire consumption.

Reduction of training costs. There is a shortage of qualified welders in the labour market today. Companies spend huge amounts of money on finding and training welders, a lot more than they realize. Welders also constantly need to retrain and confirm their skills. This is why some companies provide workers with their training centers. Compared to paying skilled welders, it is much cheaper to have one operator manage the RWC operation and load the software (SW).

Fig. 7. Gantry RWC with two assembly stands.

Quality supervision during welding. Modern robot software improves production control, e.g. arc tracking software monitors, records, and reports welding data in real time. The data can be transferred to a central storage database via the internet (local network). Another program automatically corrects errors and provides quick problem solving in the event of an unexpected robot error, should it occur. Finally, password protection and event logging will provide a running summary of any changes to the robotic welding process over a while. These software packages are designed to help companies maintain a high standard of quality even if personnel are changed.

We hope that the arguments in this article will help you make an informed decision in favour of robotizing your production. For most manufacturers, robotization and automation should only be a matter of time. If you are going to install a robot for the first time, choose a reliable integrator who will work closely with you to develop a customized system. Technical support and training are also important for any welding automation project. Remember that the goals of automation and robotization are to reduce production costs and improve welding quality.

Rest assured, robots will help you achieve these goals!