High-quality surface preparation and interoperation protection of rolled metal products are crucial factors in ensuring maximum service life and the highest quality of protective coatings. This preparation can be achieved through shot blasting, followed by the application of a conductive protective primer on the surface of the rolled metal at the stage of its delivery to production.

Later, after the assembly of the metal structure, it is only necessary to degrease the product and protect the weld seams, which significantly reduces the time required for final surface preparation before painting.

Tehvagonmash offers various automated lines for cleaning sheet and profile rolled metal products. For higher efficiency, these lines are designed and customized according to the specific production conditions of each individual customer.

By performing a full range of services — from designing the line and its power supply system, manufacturing, installation, commissioning, and personnel training — we strive to fully meet the customer’s requirements and relieve them of any tasks outside their core activities.

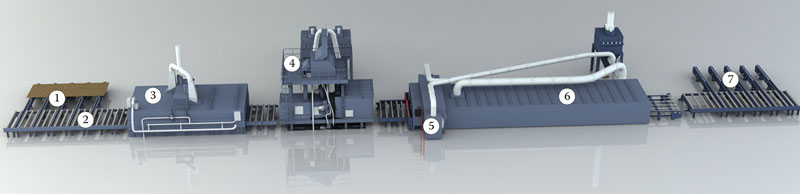

Standard Equipment Configuration:

- Feeding conveyor

- Transportation system

- Pre-drying and heating chamber

- Shot blasting chamber

- Priming chamber

- Drying chamber

- Receiving conveyor

The traditional configuration of the metal cleaning and preservation line manufactured by Tehvagonmash includes the above equipment.

Upon the customer’s request, the line can be additionally equipped with an air-blow chamber designed to remove water, ice, snow, and dirt from the metal surface.

Pre-Drying and Heating Chamber

As the rolled metal passes through the pre-drying and heating chamber (operating at a temperature of up to 250°C), it is dried from moisture and oil residues and heated to 35–40°C.

The absence of moisture prevents shot clumping in the blasting chamber, while preheating ensures more effective surface cleaning.

This temperature also improves paint adhesion and significantly reduces drying time during subsequent stages.

Drying efficiency is enhanced through forced air convection. A portion of the heated circulating air, when additional heat is required, is redirected via an insulated duct to the final drying chamber.

Energy sources can include natural gas, diesel fuel, electricity, or superheated steam.

To maintain balanced air exchange between the pre-drying and final drying chambers, the system uses synchronized air intake and exhaust dampers, automatically adjusting airflow as needed.

Shot Blasting Chamber

After pre-drying, the rolled metal enters the shot blasting chamber via a roller conveyor.

At the entrance, a photoelectric sensor detects the height of the metal and controls the automatic adjustment of the cleaning brushes.

The chamber cleans the surface to the second degree in accordance with GOST 9.402-80 (SA 2.5 / SIS 055900), removing rust, scale, and contaminants from both sides.

Depending on the maximum dimensions of the processed metal, the chamber can be equipped with 4 to 8 blasting turbines, installed at optimal angles to eliminate shadow zones.

The inner surfaces of the chamber are lined with wear-resistant manganese steel plates.

Since blasting turbines operate under intensive abrasive wear, Tehvagonmash manufactures them using high-strength materials, ensuring a long service life.

Proper cleaning also requires the removal of residual shot from the metal surface. To achieve this, the chamber is equipped with brushes and compressed air blow-off systems.

Priming and Painting Chamber

After shot blasting, the rolled metal enters the priming chamber.

To minimize paint consumption, the chamber uses sensors to detect the product’s dimensions and apply primer strictly onto the surface.

The coating equipment ensures a layer thickness of 15–20 µm.

To prevent damage to the freshly applied coating, the metal is transported using a chain conveyor with support elements, which minimizes contact with the painted surface.

Excess paint is captured by an airflow system and directed to labyrinth filters, after which cleaned air is discharged into the atmosphere.

Drying Chamber

The primer drying chamber operates in a recirculation mode, supplying heated air from the pre-drying chamber and adding 10–15% fresh air intake to avoid solvent oversaturation.

The drying temperature ranges from 30°C to 80°C, depending on the primer type.

Like in the painting chamber, the chain conveyor system minimizes damage to the freshly coated surface.

The line is equipped with special air filters that ensure 92–98% purification of the exhaust air.

Control System

The control system is based on a Siemens S7 programmable controller (Germany).

Using PLC technology allows for centralized measurement, diagnostics, and fault analysis, which makes the line more efficient and cost-effective.

Comprehensive Approach

At the final delivery stage, we provide supervised installation, commissioning, and personnel training.

With our extensive experience, highly qualified specialists, in-house production and technical facilities, and strong partnerships with numerous research and manufacturing organizations,

NPF “Tehvagonmash” is always ready to efficiently, comprehensively, and promptly solve various technical modernization challenges.

We will be pleased to consider you as our partner and are open to cooperation in the development, organization of production, and supply of new types of products.