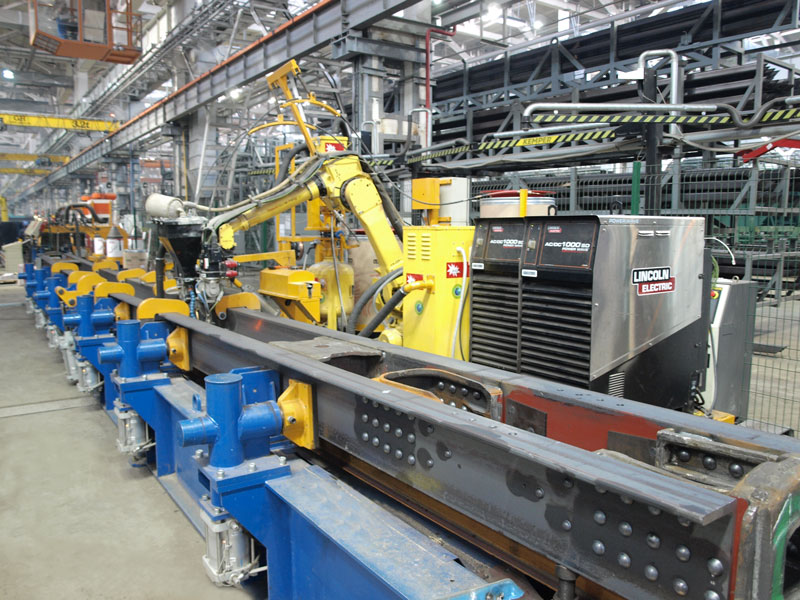

Production line for logitudinal welding of hatch gondola car center sill

The system allows to perform welding of workpieces in "normal" position as well as in "reverse" position ensuring reverse deflection during welding in order to prevent welding deformations.

Robots application allows to perform fast and flexible changeover to different items. In this case the robot is programmed for welding start and ending, overcoming of obstacles during the process of welding when the item has inner population of reinforcement elements.

One of the equipment peculiarities is the ability to weld on v-shaped gap from 0 to 12 mm by means of META laser welding seam tracking system (UK). The tracking system traces the size of the gap in the butt joint and transfers data to the robot controller.

After analyzing the received information the robot controller gives a command to the power sources and feeding mechanizms to change parameters of welding without interruption of welding process.

Flux recirculation system allows to feed the flux to the welding zone and to collect unused flux and slag crust after welding without operator in automatic mode.

Video

Specifications:

| 1. | Overall dimensions of the detail, mm | 12960х610х500 |

| 2. | Welding stand | |

| Center sill longitudinal positioning unit | folding catches | |

| Center sill transversal positioning unit | pneumatic | |

| Center sill deflection unit | pneumatic | |

| Deflection total force, kgf | 24000 | |

| Deflection, mm | 100 | |

| Center sill vertical catch unit | pneumatic | |

| Support drive system | pneumatic | |

| Support type | adjustable | |

| Support turning angle, degrees | 90 | |

| 3. | Transportation system: | |

| Platform motion drive | electromechanical | |

| Number of platforms, pcs. | 2 | |

| Drive power, kWt | 1 | |

| Cruising speed, m/h | 450 | |

| Welding speed, m/h | 20 … 120 | |

| Welding speed control type | frequency | |

| Seam type | butt seam | |

| Welding type | Robotic, flux welding | |

| Robot | Fanuc M-710iC/50 | |

| Number of robots, pcs. | 2 | |

| Seam tracking system | laser, SmartLazerPilot | |

| Welding source type | Power Wave ACDS 1000SD | |

| 4. | Installed capacity, kWt | 3 |

| 5. | Working air pressure, mPa | 0,7 … 0,8 |

| 6. | Air consumption, m3/h | 20 |

| 7. | Overall dimenstions, mm | 40040х5020х1900 |

| 8. | Weight, kg | 23000 |